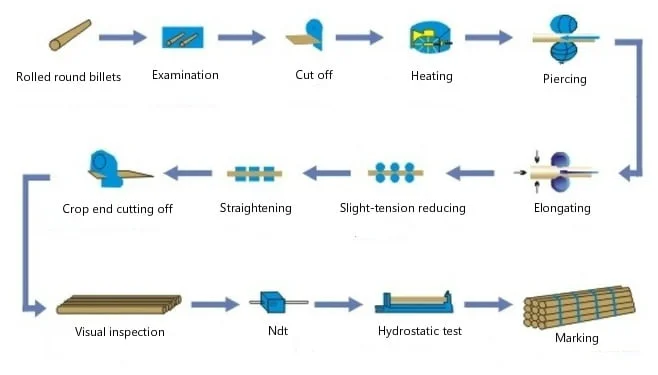

Seamless tubes are essential components in high-performance industries such as aerospace, automotive, and chemical processing, where durability, precision, and leak-proof integrity are crucial. Unlike seamed tubes, which are formed by welding rolled steel, seamless tubes are produced from a solid billet, ensuring uniform strength and superior pressure resistance. But what makes their manufacturing process unique? Let’s examine the key steps involved in creating high-quality seamless steel tubes.

1. Billet Selection & Preparation

– High-quality steel billets are carefully selected and inspected for defects.

– Surface cleaning removes impurities to ensure uniformity before processing.

2. Heating & Piercing

– Billets are heated to optimal forging temperatures in a controlled furnace.

– A piercing mill drills a hollow cavity through the center, forming a rough shell.

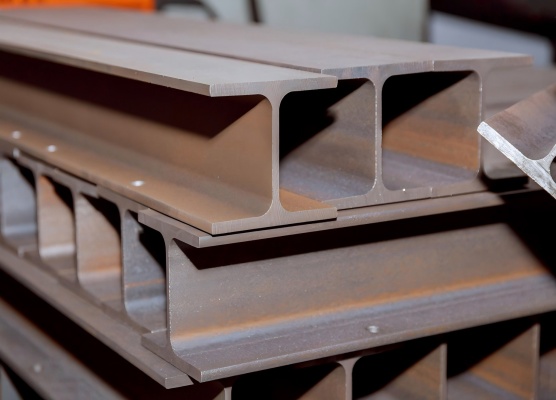

3. Rolling & Sizing

– The pierced shell undergoes hot rolling to refine dimensions and wall thickness.

– Mandrel mills or plug mills stretch and shape the pipe to precise specifications.

4. Stretch Reduction & Calibration

– The pipe is elongated and thinned using stretch-reducing mills.

– Rollers adjust outer diameter while maintaining uniform thickness.

5. Cooling & Straightening

– Controlled cooling (air or water) stabilizes the pipe’s microstructure.

– Straightening machines correct bends or distortions for perfect alignment.

6. Cutting to Length

– Automated saws cut pipes into custom sizes based on end-use requirements.

7. Heat Treatment

– Processes like annealing, normalizing, or quenching enhance strength and ductility.

8. Surface Treatment

– Descaling, pickling, or polishing ensures a smooth, corrosion-resistant finish.

9. Quality Assurance & Testing

– Rigorous checks include dimensional accuracy, hydrostatic pressure tests, ultrasonic flaw detection, and mechanical property validation.

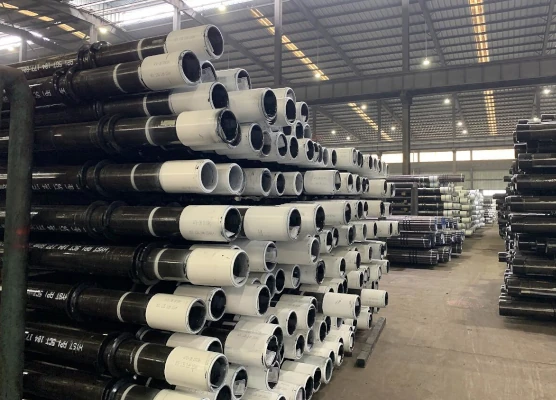

10. Packaging & Dispatch

– Pipes are coated, bundled, and labeled for secure shipping to global industries.