A carbon steel elbow is a type of pipe fitting design to change the direction of fluid flow in piping systems. Manufactured from high-quality carbon steel, these elbows are widely use in industrial applications due to their durability, strength, and cost-effectiveness.

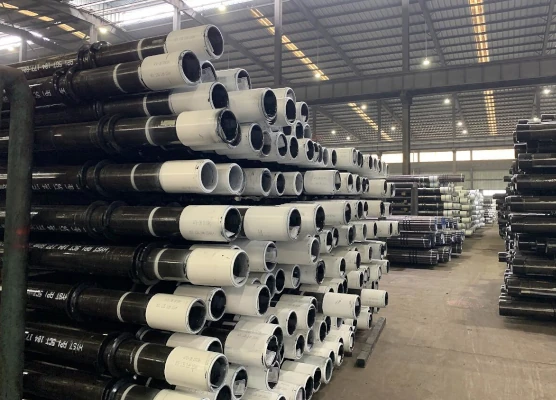

- API 5L Seamless pipeline

Carbon Steel Elbow Welded Seamless Pipe Fittings

Email:

sales@imristeel.com

Phone:

+86 13646172523

Quote Now

Product Detail

Chemical Component

Related Products

Product Details

Standard:

GB/T 12459-2017 ASTM A234 EN 10253-2 JIS B2311

Grade:

20# Q235 16Mn WPB WPC

Degree:

30° 45° 60° 90° 180°, customized degree

Connection Type:

Welding, flange, threaded, socket

Wall thickness:

STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS

Place of origin:

Baotou, China(Mainland)

Application:

Petrochemical industry

Technique:

Hot Rolled, Seamless

Certification:

ASTM

Surface Treatment:

According to customers request

Alloy Or Not:

No

Radius:

1.5D,1D,2.5D,3D,5D 10D, 20D

Supply Ability:

( 180.0000 )Ton/Tons per year

End:

Bevel end/BE/buttweld

Specification:

steel elbow

Brand:

Baotou steel

Technique:

seamless

Finish:

Hot Rolled

Chemistry Component

| Element | Content Range | Key Function/lmpact |

| Carbon(C) | 0.25%~ 0.35% | Enhances strength and hardness;excess reduces weldability and toughness |

| Manganese (Mn) | 0.29%~ 1.06% | Improves strength,refines grain structure,and neutralizes sulfur’s negative effects. |

| Silicon(Si) | 0.10%~ 0.35% | Acts as a deoxidizer,enhances strength,and improves high- temperature performance |

| Sulfur (S) | ≤0.05% | Causes hot brittleness;controlled for better ductility. |

| Phosphorus (P) | ≤0.04% | Increases cold brittleness;strictly limited. |

| Others

| Cr,Ni,Cu≤ 0.30% | Trace elements for specific applications(e.g.,corrosion resistance). |

Mechanical Performance

| Property | ASTM A234 WPB | EN 10253-2 | JIS B2311 | Test Standard |

| Tensile Strength | ≥415 MPa (60,000 psi) | ≥360 MPa | ≥400 MPa | ASTM A370/EN ISO 6892-1 |

| Yield Strength | ≥240 MPa (35,000 psi) | ≥235 MPa | ≥245 MPa | ASTM A370/EN ISO 6892-1 |

| Elongation (50mm Gauge) | ≥20% | ≥25% | ≥20% | ASTM A370/EN ISO 6892-1 |

| Hardness(Brinell HB) | ≤197 HB | ≤200 HB | ≤201 HB | ASTM E10/ISO 6506-1 |

| Impact Toughness | ≥20J(-29℃ Charpy V) | ≥27J(20℃ Charpy V) | ≥20J(-20℃ Charpy V) | ASTM A370/ISO 148-1 |

Related products

Size 2.4" to 4.5" API 5CT N80Q Tubing Pipe

Read More

API 5CT P110 Casing for Ultra-Deep Wells

Read More

Carbon Steel Elbow Welded Seamless Pipe Fittings

Read More

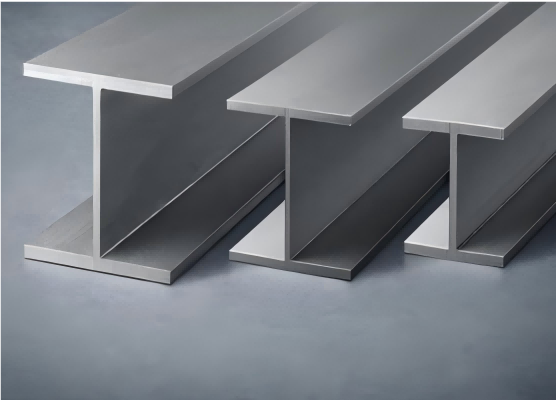

EN10025 S275JR H-Beam Steel

Read More

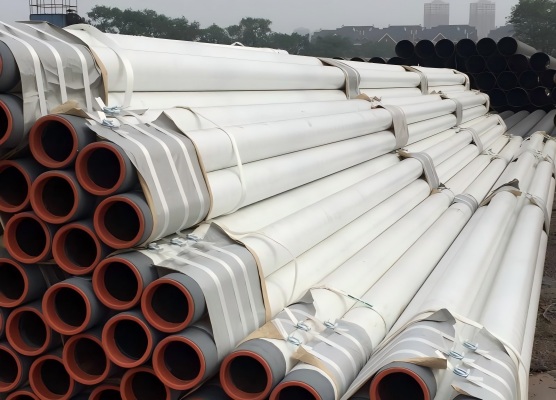

3PP Anti-Corrosion Coated Pipe

Read More

GB/T 8162-2018 42CrMo Seamless Structure Tube

Read More

Sour Service API 5CT N80Q Tubing

Read More

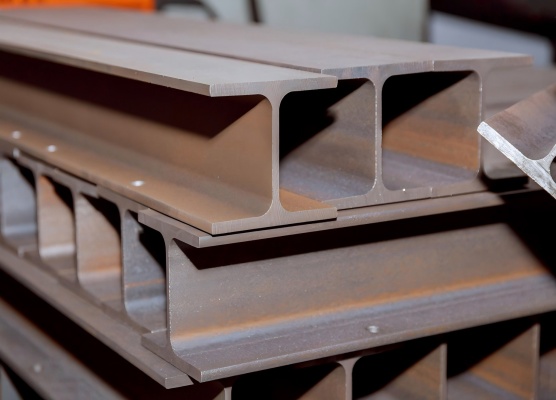

GB/T 11263 H Beam Steel

Read More