IMRI’s N80-1 tubing is certified to API 5CT. The LTC thread provides enhanced gas-tight integrity, enabling metal-to-metal sealing at internal pressures above 8,500 psi, ideal for hydrogen-containing wells and hydraulic fracturing operations

- Tubing, Tubing & Casing Pipe

API 5CT N80-1 Tubing Pipe With LTC Thread

Email:

sales@imristeel.com

Phone:

+86 13646172523

Quote Now

Product Detail

Packaging & Delivery

Related Products

Product Detail

Established in 1954, the factory has an annual capacity of up to 10 million tons. With five oil casing production lines, it can provide oil casing with OD 60.3mm-114.3mm, which strictly conforms to API 5CT standard. According to API 5B,we can provide BTC/LTC/STC threaded connections and equipped with Premium Threaded.

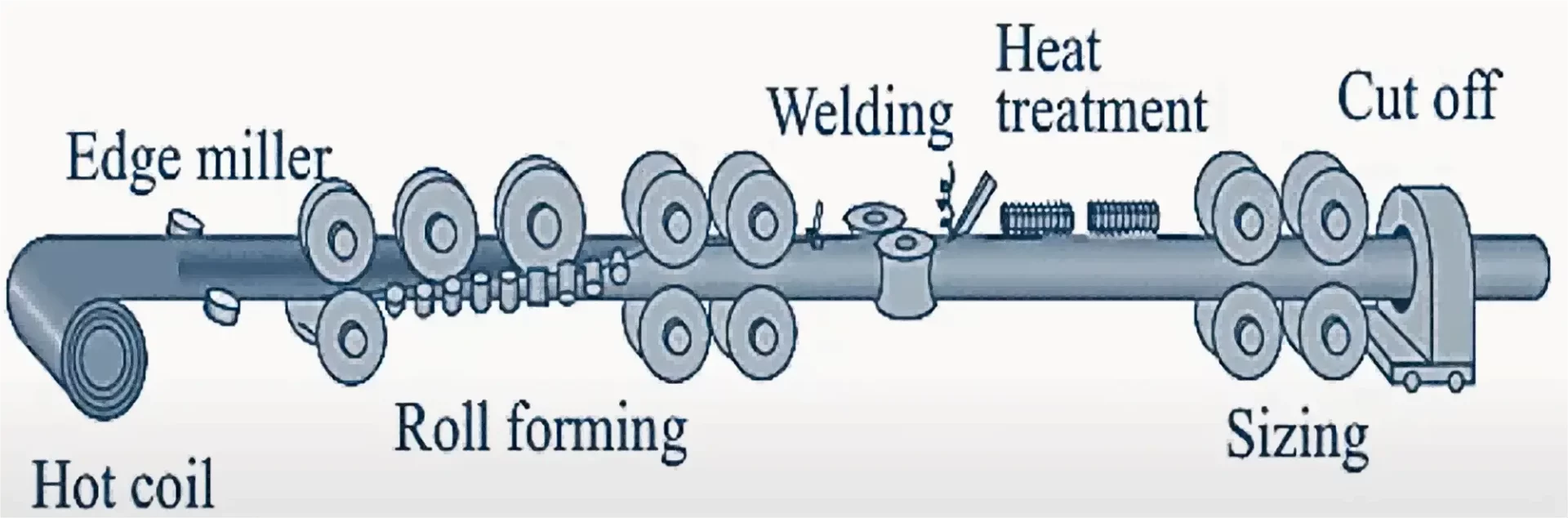

Manufacturing Process

API 5CT K55 is a steel pipe made by either a seamless process or an EW welding process.

Common EW processes include ERW and EFW.

ERW (Electric Resistance Welding) is typically used for tubes with thinner walls, while EFW (Electrofusion Welding) is used for tubes with thicker walls, which are able to withstand higher pressures.

Coupling materials, coupling blanks and coupling materials must be manufactured using a seamless process.

Quick Details

Standard:

API 5CT/5B

Grade:

N80-1

Thickness:

2.9-60mm

section shape:

Round

Outer Diameter:

Ф60.3-114.3

Place of origin:

Baotou, China(Mainland)

Function:

Transportation of oil and gas

Technique:

Hot Rolled, Seamless

Certification:

API 5CT/5B

Surface Treatmen:

According to customers request

Alloy Or Not:

No

Type:

EU NU

Supply Ability:

( 180.0000 )Ton/Tons per year

Installation Position:

Center of casing cavity

Sealing Pressure:

≥5,000 psi

Brand:

Baotou steel

Application:

Medium and high-pressure oil and gas wells

Risk of failure:

Corrosion Perforation; Thread Leakage; Wax Plugging

Chemistry Component

| Grade | C | Mn | Mo | Cr | Nb | Ni | Cu | P | S | Si | ||||

| min | max | min | max | min | max | min | max | max | max | max | max | max | max | |

| J55 | — | — | — | — | — | — | — | — | — | — | — | 0.030 | 0.030 | — |

| N80-1 | — | — | — | — | — | — | — | — | — | — | — | 0.030 | 0.030 | — |

| N80Q | — | — | — | — | — | — | — | — | — | — | — | 0.030 | 0.030 | — |

| L80 – 1 | — | 0.43a | — | 1.90 | — | — | — | 1.50 | — | 0.25 | 0.35 | 0.030 | 0.030 | 0.45 |

| L80 – 9Cr | — | 0.15 | 0.30 | 0.60 | 0.90 | 1.10 | 8.00 | 10.0 | — | 0.50 | 0.25 | 0.020 | 0.010 | 1.00 |

| L80 – 13Cr | 0.15 | 0.22 | 0.25 | 1.00 | — | — | 12.0 | 14.0 | — | 0.50 | 0.25 | 0.020 | 0.010 | 1.00 |

| C90 | — | 0.35 | — | 1.20 | 0.25b | 0.85 | — | 1.50 | — | 0.99 | — | 0.020 | 0.010 | — |

| P110 | — | — | — | — | — | — | — | — | — | — | — | 0.030e | 0.030e | — |

Tensile test requirements

| Grade | Total Elongation Under Load % | Yield Strength MPa | Tensile Strength min MPa | |

| min | max | |||

| J55 | 0.5 | 379 | 552 | 517 |

| N80-1 | 0.5 | 552 | 758 | 689 |

| N80Q | 0.5 | 552 | 758 | 689 |

| L80 – 1 | 0.5 | 552 | 655 | 655 |

| L80 – 9Cr | 0.5 | 552 | 655 | 655 |

| L80 – 13Cr | 0.5 | 552 | 655 | 655 |

| N80-1 | 0.5 | 552 | 655 | 655 |

| C90 | 0.5 | 621 | 724 | 689 |

| P110 | 0.6 | 758 | 965 | 862 |

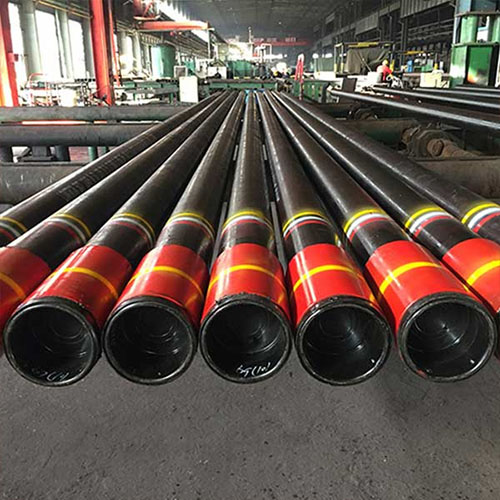

Color Discrimination

| Grade | Type | Straps for products longer than 1.8 meters Quantity and color | Coupling color | |

| The whole coupling | Brand | |||

| H40 | No belt or black belt, to be selected by the manufacturer | not have | Same as for the pipeline | |

| J55 | A sea of green | Bright green | not have | |

| K55 | Two emerald green | Bright green | not have | |

| N80 | 1 | One red | red | not have |

| N80 | Q | One is red, the other emerald green | red | green |

| R95 | One brown | brown | not have | |

| L80 | 1 | One red, one brown | red | One brown |

| L80 | 3Cr | One red and one white | red | One white |

| L80 | 9Cr | One red, one brown, two yellow | not have | Two yellows |

| L80 | 13Cr | One red, one brown and one yellow | not have | One yellow |

| C90 | A purple one | purple | not have | |

| T95 | One silver | silvery | not have | |

| C110 | One white, two brown | white | Two brown | |

| P110 | One white | white | not have | |

| Q125 | One orange | orange | not have | |

Packaging & Delivery

Packaging & Delivery

· Thread: Screwing Plastic thread retainer + applying thread grease

· Pipe End: Covered HDPE crash cap (embedded foam cushion)

· Packing: Steel strapping in hexagonal bundles or as per customer’s request .(as pictures)

· Pipe End: Covered HDPE crash cap (embedded foam cushion)

· Packing: Steel strapping in hexagonal bundles or as per customer’s request .(as pictures)

Packaging & Shipping

· Minimum order quantity: 5 tons

· Price: FOB at Xin’gang port in Tianjin or CIF or CFR

· Payment: 30% deposit in advance, the balance against the copy of B/L; or 100% L/C, etc

· Lead Time: within 10-25 workdays normally

· Sample: Free sample is available.

· Price: FOB at Xin’gang port in Tianjin or CIF or CFR

· Payment: 30% deposit in advance, the balance against the copy of B/L; or 100% L/C, etc

· Lead Time: within 10-25 workdays normally

· Sample: Free sample is available.

Related products

GB/T 18248 35CrMo Gas Cylinder Tube

Read More

GB/T 17396 27SiMn hydraulic pillar pipe

Read More

GB/T 5310-2017 Seamless Alloy Steel Pipe 12Cr1MoV

Read More

Size 2.4" to 4.5" API 5CT N80Q Tubing Pipe

Read More

OCTG Casing API 5CT K55 Oil Gas Pipe

Read More

API 5L Seamless Pipeline X42-X70 PSL1 Oil and Gas Industry

Read More

37Mn Gas Cylinder Tube

Read More

API 5L X60Q Oil Gas Seamless Pipeline

Read More