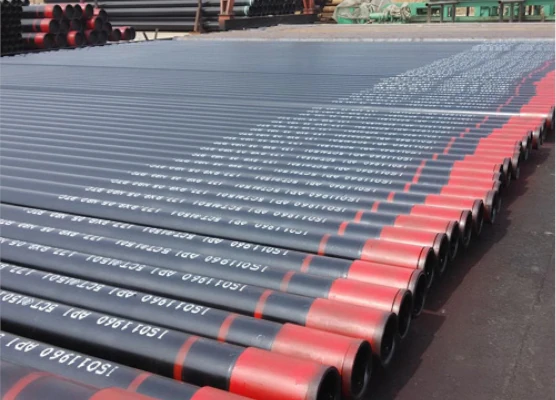

Constructed from J55 grade steel, it offers a balanced combination of medium-strength mechanical properties and resistance to sulfide stress cracking (SSC), making it a reliable choice for tubing strings in various well environments.

- Tubing, Tubing & Casing Pipe

OCTG API 5CT J55 Oil Well Tubing

Email:

sales@imristeel.com

Phone:

+86 13646172523

Quote Now

Product Detail

Packaging & Delivery

Related Products

Product Detail

Tubing is a key component in oil extraction operations.Processed into tubes with specific diameters and wall thicknesses through an advanced hot rolling process. In order to enhance the corrosion resistance, the tubing will be treated with a special anti-corrosion coating, effectively resisting the erosion of complex media in the oil well. These processes guarantee the long-term stable operation of the tubing in the harsh oil well environment.

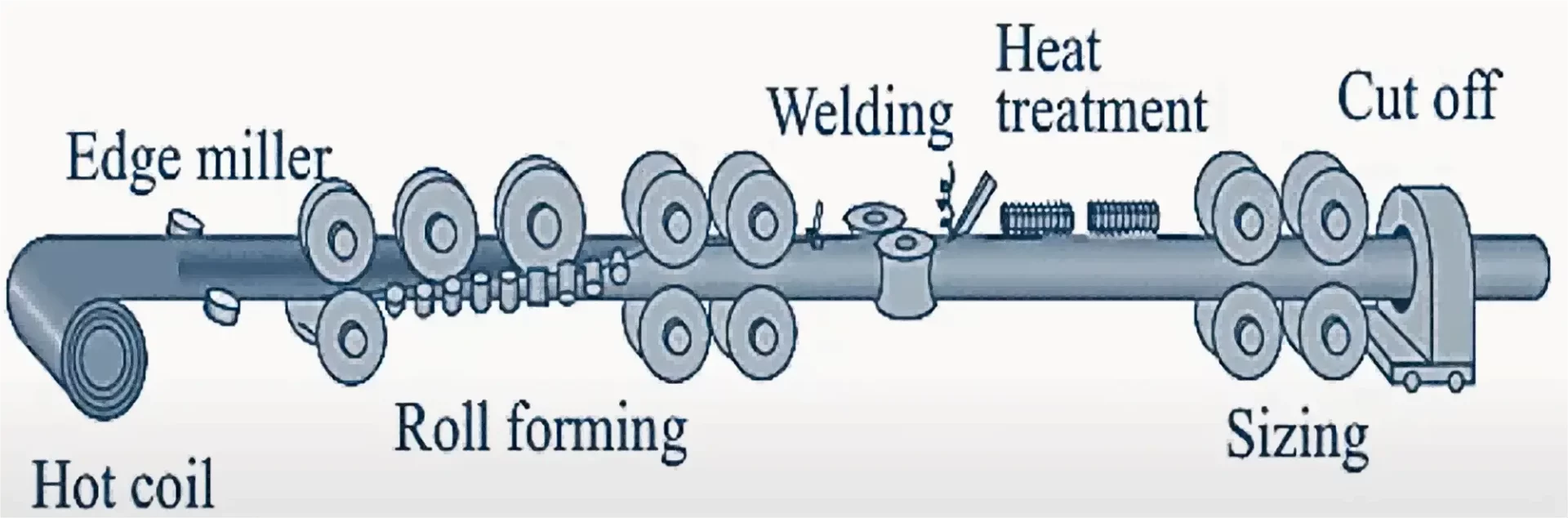

Manufacturing Process

API 5CT J55 is a steel pipe made by either a seamless process or an EW welding process.

Common EW processes include ERW and EFW.

ERW (Electric Resistance Welding) is typically used for tubes with thinner walls, while EFW (Electrofusion Welding) is used for tubes with thicker walls, which are able to withstand higher pressures.

Coupling materials, coupling blanks and coupling materials must be manufactured using a seamless process.

Quick Details

Standard:

API 5CT/5B

Grade:

J55

Thickness:

2.9-60mm

section shape:

Round

Outer Diameter:

Ф60.3-114.3

Place of origin:

Baotou, China(Mainland)

Function:

Transportation of oil and gas

Technique:

Hot Rolled, Seamless

Certification:

API 5CT/5B

Surface Treatmen:

According to customers request

Alloy Or Not:

No

Type:

EU NU

Supply Ability:

( 180.0000 )Ton/Tons per year

Installation Position:

Center of casing cavity

Sealing Pressure:

≥5,000 psi

Brand:

Baotou steel

Application:

Medium and low pressure oil and gas Wells

Risk of failure:

Corrosion Perforation; Thread Leakage; Wax Plugging

Chemistry Component

| Grade | C | Mn | Mo | Cr | Nb | Ni | Cu | P | S | Si | ||||

| min | max | min | max | min | max | min | max | max | max | max | max | max | max | |

| J55 | — | — | — | — | — | — | — | — | — | — | — | 0.030 | 0.030 | — |

| N80-1 | — | — | — | — | — | — | — | — | — | — | — | 0.030 | 0.030 | — |

| N80Q | — | — | — | — | — | — | — | — | — | — | — | 0.030 | 0.030 | — |

| L80 – 1 | — | 0.43a | — | 1.90 | — | — | — | 1.50 | — | 0.25 | 0.35 | 0.030 | 0.030 | 0.45 |

| L80 – 9Cr | — | 0.15 | 0.30 | 0.60 | 0.90 | 1.10 | 8.00 | 10.0 | — | 0.50 | 0.25 | 0.020 | 0.010 | 1.00 |

| L80 – 13Cr | 0.15 | 0.22 | 0.25 | 1.00 | — | — | 12.0 | 14.0 | — | 0.50 | 0.25 | 0.020 | 0.010 | 1.00 |

| C90 | — | 0.35 | — | 1.20 | 0.25b | 0.85 | — | 1.50 | — | 0.99 | — | 0.020 | 0.010 | — |

| P110 | — | — | — | — | — | — | — | — | — | — | — | 0.030e | 0.030e | — |

Tensile test requirements

| Grade | Total Elongation Under Load % | Yield Strength MPa | Tensile Strength min MPa | |

| min | max | |||

| J55 | 0.5 | 379 | 552 | 517 |

| N80-1 | 0.5 | 552 | 758 | 689 |

| N80Q | 0.5 | 552 | 758 | 689 |

| L80 – 1 | 0.5 | 552 | 655 | 655 |

| L80 – 9Cr | 0.5 | 552 | 655 | 655 |

| L80 – 13Cr | 0.5 | 552 | 655 | 655 |

| N80-1 | 0.5 | 552 | 655 | 655 |

| C90 | 0.5 | 621 | 724 | 689 |

| P110 | 0.6 | 758 | 965 | 862 |

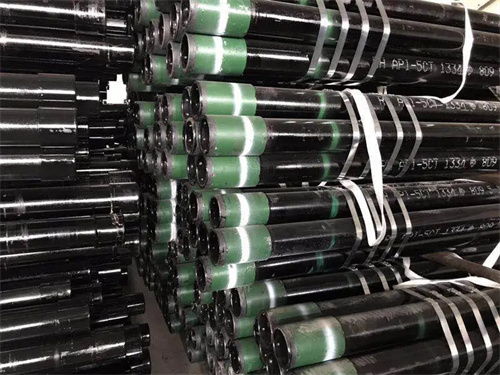

Color Discrimination

| Grade | Type | Straps for products longer than 1.8 meters Quantity and color | Coupling color | |

| The whole coupling | Brand | |||

| H40 | No belt or black belt, to be selected by the manufacturer | not have | Same as for the pipeline | |

| J55 | A sea of green | Bright green | not have | |

| K55 | Two emerald green | Bright green | not have | |

| N80 | 1 | One red | red | not have |

| N80 | Q | One is red, the other emerald green | red | green |

| R95 | One brown | brown | not have | |

| L80 | 1 | One red, one brown | red | One brown |

| L80 | 3Cr | One red and one white | red | One white |

| L80 | 9Cr | One red, one brown, two yellow | not have | Two yellows |

| L80 | 13Cr | One red, one brown and one yellow | not have | One yellow |

| C90 | A purple one | purple | not have | |

| T95 | One silver | silvery | not have | |

| C110 | One white, two brown | white | Two brown | |

| P110 | One white | white | not have | |

| Q125 | One orange | orange | not have | |

Packaging & Delivery

Packaging & Delivery

· Thread: Screwing Plastic thread retainer + applying thread grease

· Pipe End: Covered HDPE crash cap (embedded foam cushion)

· Packing: Steel strapping in hexagonal bundles or as per customer’s request .(as pictures)

· Pipe End: Covered HDPE crash cap (embedded foam cushion)

· Packing: Steel strapping in hexagonal bundles or as per customer’s request .(as pictures)

Packaging & Shipping

· Minimum order quantity: 5 tons

· Price: FOB at Xin’gang port in Tianjin or CIF or CFR

· Payment: 30% deposit in advance, the balance against the copy of B/L; or 100% L/C, etc

· Lead Time: within 10-25 workdays normally

· Sample: Free sample is available.

· Price: FOB at Xin’gang port in Tianjin or CIF or CFR

· Payment: 30% deposit in advance, the balance against the copy of B/L; or 100% L/C, etc

· Lead Time: within 10-25 workdays normally

· Sample: Free sample is available.

Related products

API 5CT N80-1 for High-Pressure Isolation

Read More

GB/T 11263 H Beam Steel

Read More

GB/T 5310-2017 15CrMoG Seamless Alloy Steel Pipe

Read More

34CrMo4 Gas Cylinder Tube

Read More

Dual Powder System(DPS) Pipeline Coating

Read More

API 5CT P110 Tubing with Premium Connections

Read More

API 5L ASTM A106 Gr.B Seamless Steel Pipe

Read More

API 5L X65Q Seamless Pipeline for Sour Service

Read More