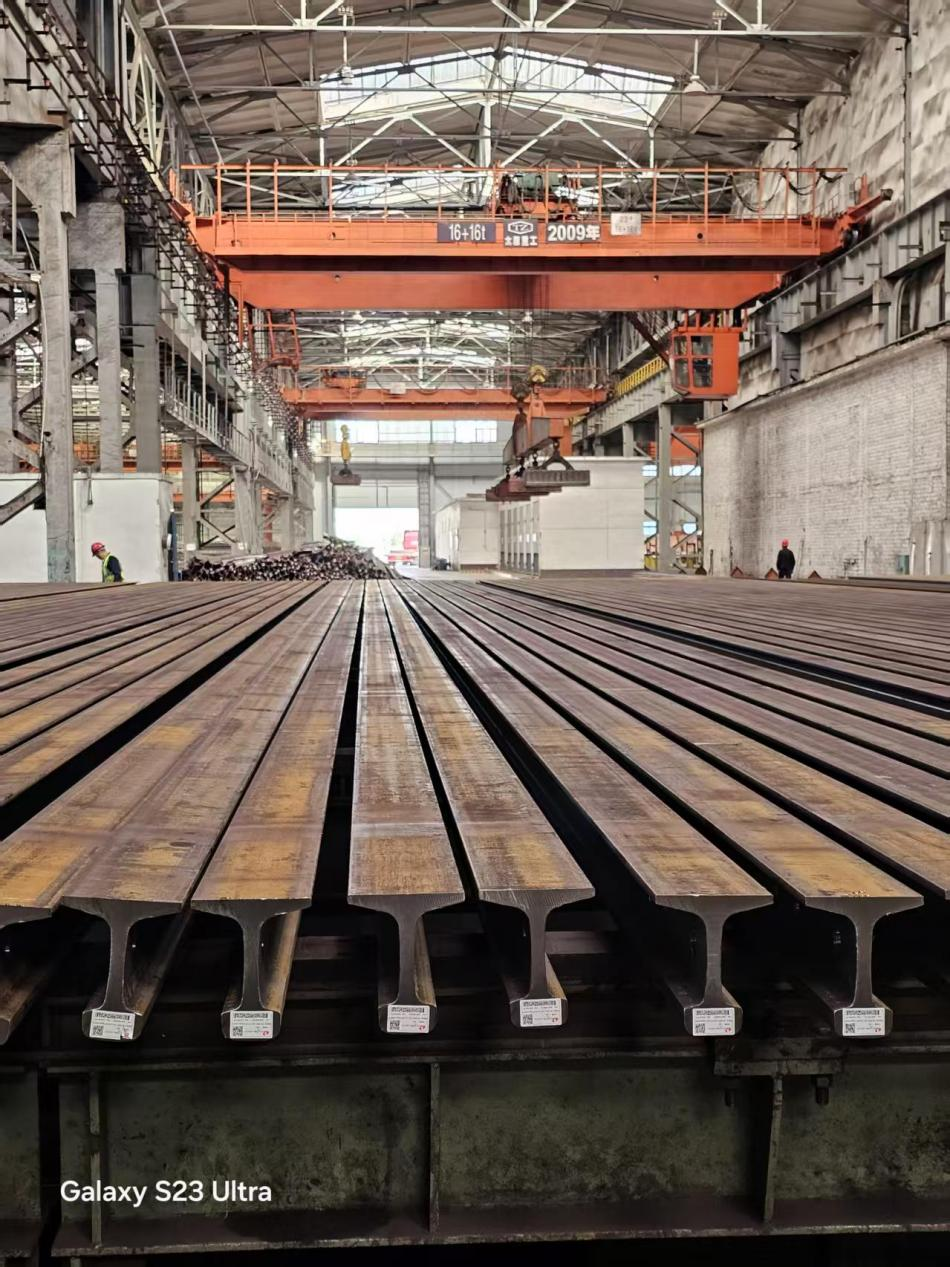

P50 rails, also known as GOST R50 rails, are heavy-duty rails with high load carrying capacity and compression resistance, and are commonly use in high-speed railways and heavy transportation lines. It is commonly use in high-speed railroads and heavy transportation lines.P50 rails comply with the Russian standard GOST, commonly use materials are 50Mn or U71Mn, the weight of each meter is about 51.514 kilograms, and the standard length is 12.5 meters, which is in accordance with the GB2585-2007 standard.

- Steel Rail

Heavy Rail of P50/R50 Rails

Email:

sales@imristeel.com

Phone:

+86 13646172523

Quote Now

Product Detail

Packaging & Delivery

Related Products

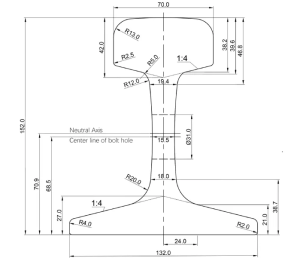

Drawing and Size Tolerance

| Tolerance of P50 Rail Type (mm) | |

| Head width | ±0.5 |

| Foot width | +1.0,-0.5 |

| Web thickness | +0.8,-0.5 |

| Rail height | ±0.8 |

| Point height | +1.0,-0.5 |

| Web height | +0.3,-0.7 |

| Deviation of tread shape from nominal shape (along the symmetry axis) | ±0.5 |

| Convexity of foot (uniform) | 0.5 |

| Concavity of foot | Not allowed |

| Profile deviation from symmetry (asymmetry) | ±1.3 |

| Permitted deviation from rail length, mm | ±20 |

Chemistry Component

| C | Si | Mn | P | S | Cr | V | AL | Other elements |

| 0.65-0.77 | 0.15-0.35 | 1.10-1.50 | ≤0.04 | ≤0.04 | — | — | — | 0.20 |

| Note: Residual and tolerance of chemical component of finished rail according to U71 Mn material | ||||||||

Mechanical Properties

| Rail | Tensile strength, N/mm2 | Yield point, N/mm2 | Percent elongation, % | Contraction, % |

| P50 | ≥500 | ≥420 | ≥14.0 | ≥25.0 |

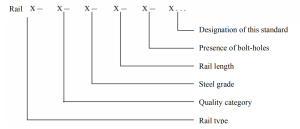

Mark

Other Notable Features:

High Tensile and Bending Strengths:P50 rails have a high ultimate tensile strength (≥500 MPa) and bending strength (≥420 MPa).

High Elongation:They also possess a minimum elongation of 14%, contributing to their durability and ability to withstand repeated stresses.

Durable and Reliable:P50 rails are commonly used on high-speed and heavy-haul railway lines to ensure the reliability and durability of railway systems.

Dimensional Accuracy and Uniformity:These rails are known for their excellent dimensional accuracy, straightness, and uniformity, which contribute to smooth train movement and reduced noise and vibration.

Heavy-Duty Design:They are designed for heavy loads and are used in various applications, including rail transportation, slide rails, temporary transportation paths, and industrial frameworks.

Railway Track Systems:P50 rails are commonly used in conjunction with rail joint bars or fishplates to provide secure and stable connections between rails.

Bull Headed Profile:P50 rails often feature a bull-headed profile, where the head is larger than the foot, providing increased strength and allowing for better wear resistance.

Packaging & Delivery

Packaging & Delivery

· Packaging Details: Bundles wrapped with strong steel trips, or according to customers’ requirements.The length of the rail can be selected as 12 meters, 12.5 meters, 18 meters, 24 meters or 25 meters.

· Port: Tianjin Port

· Lead Time: Within 20-30 days depends on the order quantity

Packaging & Shipping

· Minimum order quantity: 500 tons

· Price: FOB at Xin’gang port in Tianjin or CFR/CIF

· Payment: 30% deposit in advance, the balance against the copy of B/L; or 100% L/C, etc

· Packing: Standard seaworthy packing or as per your request .(as pictures)

· Sample: Free sample is available.

Related products

Grade P22 ASTM A335 Alloy Seamless Pipe

Read More

EN10025 S235JR H-Beam Steel

Read More

ASTM A53 10# Steel Structure Tube

Read More

APL 5L X60 Oil and Gas Pipeline

Read More

API 5CT N80-1 Tubing Pipe With LTC Thread

Read More

OCTG API 5CT J55 Oil Well Tubing

Read More

EN10025 S355J2 Structural Steel H Beams

Read More

Liquid Epoxy Coating

Read More