IMRI casing is N80-1 rate (high strength, good toughness and weldability). It is machine with BTC threads on both ends to provide reliable thread sealing and fast-tacking efficiency for medium to deep, high-pressure well completions and to withstand complex downhole loads.

- Casing

API 5CT N80-1 Casing Pipe with BTC Thread

Email:

sales@imristeel.com

Phone:

+86 13646172523

Quote Now

Product Detail

Packaging & Delivery

Related Products

Product Detail

Our petroleum casing products strictly comply with API 5CT and ISO 11960 international standards, and we provide fully traceable factory test reports. Our products cover a wide range of sizes from 4 1/2“-18 5/8” OD, and can be machined to STC/LTC/BTC threaded end or flat end designs to meet the diverse needs of onshore, offshore, and unconventional oil and gas wells. For corrosive environments (e.g. H₂S/CO₂ gas fields), we provide 3PE/FBE coatings and other anti-corrosion solutions to significantly extend the life of the column.

Raw Material Selection

Raw Material Selection

From steel billet and other raw material, chemical components analysis shall be done, in compliance with Standard Specification.Visual inspection is also taken, to prevent the defects, such as pit, crack, blowhole on surface or subsurface.

Quality Control

IMRI Steel pipes mostly come from PQF mill, the most advanced technology for producing seamless pipe world-wide.

NDT methods shall be applied to examine pipe and fittings, without destroying the serviceability of the sampling, mainly including:

*Eddy current testing

*Magnetic particle testing

*Ultrasonic testing.

NDT methods shall be applied to examine pipe and fittings, without destroying the serviceability of the sampling, mainly including:

*Eddy current testing

*Magnetic particle testing

*Ultrasonic testing.

Physical Testing

Physical testing is intended to test mechanical properties of steel in compliance with Standard Specification or Clients’ request, mainly including:

*Tensile strength test

*Yield strength test

*Elongation test

*Charpy V-notch impact test

*Hardness test (BHN, HV, RC, HRB)

*Hydrostatic test.

*Tensile strength test

*Yield strength test

*Elongation test

*Charpy V-notch impact test

*Hardness test (BHN, HV, RC, HRB)

*Hydrostatic test.

Inspection Before Shipment

The Surface, End, Marking, Packing, Quantity and Weight measurement shall be stricly done before shipment.A copy of inspection certificate shall be issued by our QC department, in the name of Baotou Steel.

Quick Details

Standard:

API 5CT/API 5B

Grade:

N80-1

Thickness:

2.9-60mm

Thread Type:

STC BTC LTC

Outer Diameter:

Ф114.3-406

Place of Origin:

Baotou, China(Mainland)

Function:

Structural Support; Wellbore Protection

Technique:

Hot Rolled; Seamless

Certification:

API 5CT/5B

Surface Treatmen:

According to customers request

Alloy Or Not:

No

length:

R1 R2 R3

Supply Ability:

( 180.0000 )Ton/Tons per year

Installation location:

Close to the open hole wall

Collapse Resistance:

≥2,000 psi

Brand:

Baotou steel

Application:

high pressure well oil and gas well

Risk of failure:

Blowouts; Formation Contamination; Borehole Deformation

Mechanical Propert

| Grade | Type | Total under load Elongation % | Yield strength megapascal | Tensile strength megapascal | Hardness a, C Maximum | Specified OD mm | Allowable hardness Variation | ||

| Min | Max | Min | HRC | HBW | HRC | ||||

| H40 | – | 0.5 | 276 | 552 | 414 | – | – | – | – |

| J55 | – | 0.5 | 379 | 552 | 517 | – | – | – | – |

| K55 | – | 0.5 | 379 | 552 | 655 | – | – | – | – |

| N80 | 1 | 0.5 | 552 | 758 | 689 | – | – | – | – |

| N80 | Q | 0.5 | 552 | 758 | 689 | – | – | – | – |

| R95 | – | 0.5 | 655 | 758 | 724 | – | – | – | – |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23.0 | 241 | – | – |

| L80 | 3Cr | 0.5 | 552 | 655 | 655 | 23.0 | 241 | – | – |

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23.0 | 241 | – | – |

| L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23.0 | 241 | – | – |

|

C90 |

– |

0.5 |

621 |

724 |

689 |

25.4 |

255 | ≤12.70 | 3.0 |

| 12.71 to 19.04 | 4.0 | ||||||||

| 19.05 to 25.39 | 5.0 | ||||||||

| ≥25.40 | 6.0 | ||||||||

|

T95 |

– |

0.5 |

655 |

758 |

724 |

25.4 |

255 | ≤12.70 | 3.0 |

| 12.71 to 19.04 | 4.0 | ||||||||

| 19.05 to 25.39 | 5.0 | ||||||||

| ≥25.40 | 6.0 | ||||||||

|

C110 |

– |

0.7 |

758 |

828 |

793 |

29 |

279 | ≤12.70 | 3.0 |

| 12.71 to 19.04 | 4.0 | ||||||||

| 19.05o to 25.39 | 5.0 | ||||||||

| ≥25.40 | 6.0 | ||||||||

| P110 | – | 0.6 | 758 | 965 | 862 | – | – | – | – |

| Q125 | – | 0.65 | 862 | 1034 | 931 | b | – | ≤12.70 | 3.0 |

| 12.71 to 19.04 | 4.0 | ||||||||

| ≥19.05 | 5.0 | ||||||||

Chemistry Component

| Grade | Type | C | Mn | Mo | Cr | Ni | Cu | P | S | Si | ||||

| Min | Max | Min | Max | Min | Max | Min | Max | Max | Max | Max | Max | Max | ||

| H40 | – | – | – | – | – | – | – | – | – | – | – | 0.030 | 0.030 | – |

| J55 | – | – | – | – | – | – | – | – | – | – | – | 0.030 | 0.030 | – |

| K55 | – | – | – | – | – | – | – | – | – | – | – | 0.030 | 0.030 | – |

| N80 | 1 | – | – | – | – | – | – | – | – | – | 0.030 | 0.030 | – | |

| N80 | Q | – | – | – | – | – | – | – | – | – | – | 0.030 | 0.030 | – |

| R95 | – | – | 0.45 | – | 1.90 | – | – | – | – | – | – | 0.030 | 0.030 | 0.45 |

| L80 | 1 | – | 0.43 | – | 1.90 | – | – | – | – | 0.25 | 0.35 | 0.030 | 0.030 | 0.45 |

| L80 | – | – | 0.15 | 0.30 | 0.60 | 0.90 | 1.10 | 8.00 | 10.0 | 0.50 | 0.25 | 0.020 | 0.010 | 1.00 |

| L80 | 13Cr | 0.15 | 0.22 | 0.25 | 1.00 | – | – | 12.0 | 14.0 | 0.50 | 0.25 | 0.020 | 0.010 | 1.00 |

| C90 | 1 | – | 0.35 | – | 1.20 | 0.25 | 0.85 | – | 1.50 | 0.99 | – | 0.020 | 0.010 | – |

| T95 | 1 | – | 0.35 | – | 1.20 | 025 | 0.85 | 0.40 | 1.50 | 0.99 | – | 0.020 | 0.010 | – |

| C110 | – | – | 0.35 | – | 1.20 | 0.25 | 1.00 | 0.40 | 1.50 | 0.99 | – | 0.020 | 0.005 | – |

| P110 | – | – | – | – | – | – | – | – | – | – | – | 0.030 | 0.030 | – |

| Q125 | 1 | – | 0.35 | – | 1.35 | – | 0.85 | – | 1.50 | 0.99 | – | 0.020 | 0.010 | – |

Color Discrimination

| Grade | Type | Straps for products longer than 1.8 meters Quantity and color | Coupling color | |

| The whole coupling | Brand | |||

| H40 | No belt or black belt, to be selected by the manufacturer | not have | Same as for the pipeline | |

| J55 | A sea of green | Bright green | One white | |

| K55 | Two emerald green | Bright green | not have | |

| N80 | 1 | One red | red | not have |

| N80 | Q | One is red, the other emerald green | red | green |

| R95 | One brown | brown | not have | |

| L80 | 1 | One red, one brown | red | One brown |

| L80 | 3Cr | One red and one white | red | One white |

| L80 | 9Cr | One red, one brown, two yellow | not have | Two yellows |

| L80 | 13Cr | One red, one brown and one yellow | not have | One yellow |

| C90 | A purple one | purple | not have | |

| T95 | One silver | silvery | not have | |

| C110 | One white, two brown | white | Two brown | |

| P110 | One white | white | not have | |

| Q125 | One orange | orange | not have | |

Chemistry Component

| Scope 1 | Scope 2 | Scope 3 | |

| Tubes (PE/T and C/SF) | 4.88 to 7.62 1.83 | 7.62 to 10.36 one point five two | 10.36 to 14.63 1.83 |

| Oil pipes and casing used as oil pipes (PE/T and C/SF) | 6.10 to 7.32b 0.61 | 8.53 to 9.75 point six one | 11.58 to 12.80d 0.61 |

| Overall joint tubing (including IJ/PE and IJ/SF) | 6.10 to 7.92 0.61 | 8.53 to 10.36 0.61 | 11.58 to 13.72 0.61 |

| short section | Length: 0.61,0.91,1.22,1.83,2.44,3.05 and 3.669 Tolerance: ±0.076 | ||

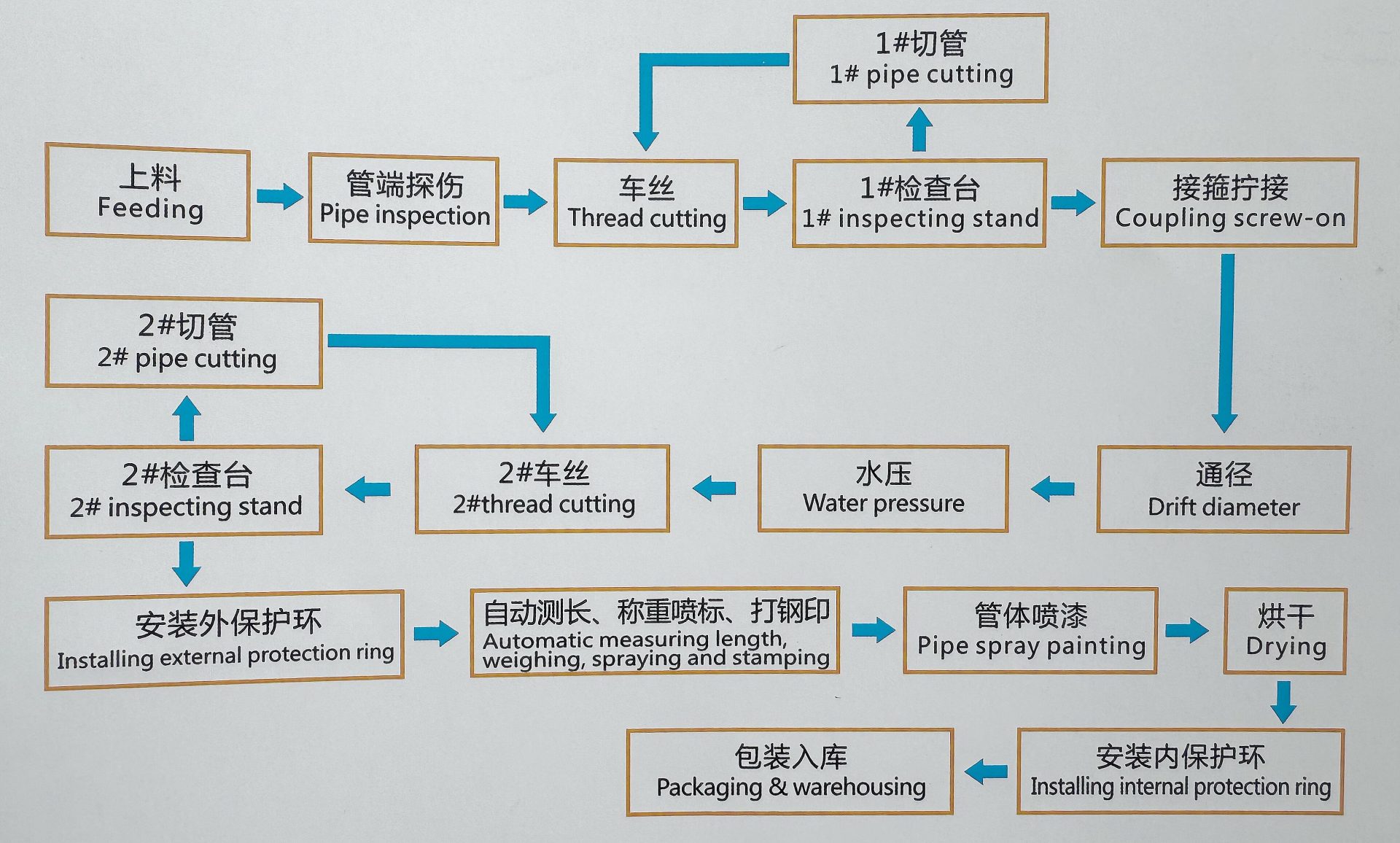

Thread Cutting Process of Casing

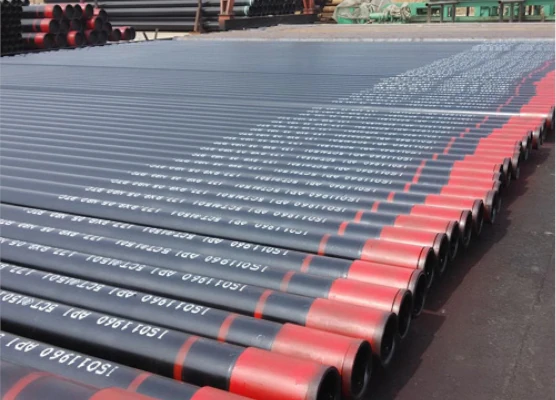

Packaging & Delivery

Packaging & Delivery

· Thread: Screwing Plastic thread retainer + applying thread grease

· Pipe End: Covered HDPE crash cap (embedded foam cushion)

· Packing: Steel strapping in hexagonal bundles or as per customer’s request .(as pictures)

· Pipe End: Covered HDPE crash cap (embedded foam cushion)

· Packing: Steel strapping in hexagonal bundles or as per customer’s request .(as pictures)

Packaging & Shipping

· Minimum order quantity: 5 tons

· Price: FOB Xin’gang port in Tianjinor CIF or CFR

· Payment: 30% deposit in advance, the balance against the copy of B/L; or 100% L/C, etc

· Lead Time: within 10-25 workdays normally

· Sample: Free sample is available.

· Price: FOB Xin’gang port in Tianjinor CIF or CFR

· Payment: 30% deposit in advance, the balance against the copy of B/L; or 100% L/C, etc

· Lead Time: within 10-25 workdays normally

· Sample: Free sample is available.

Related products

ASTM A53 10# Steel Structure Tube

Read More

GB/T 18248 42CrMo Gas Cylinder Tube

Read More

R65 Rail Pads

Read More

API 5CT Petroleum Casing Coupling Material

Read More

Sour Service API 5CT N80Q Tubing

Read More

OCTG Casing API 5CT K55 Oil Gas Pipe

Read More

Size 2.4" to 4.5" API 5CT N80Q Tubing Pipe

Read More

API 5CT N80-1 for High-Pressure Isolation

Read More