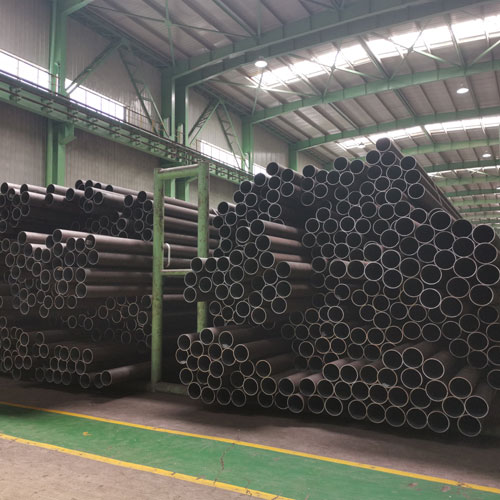

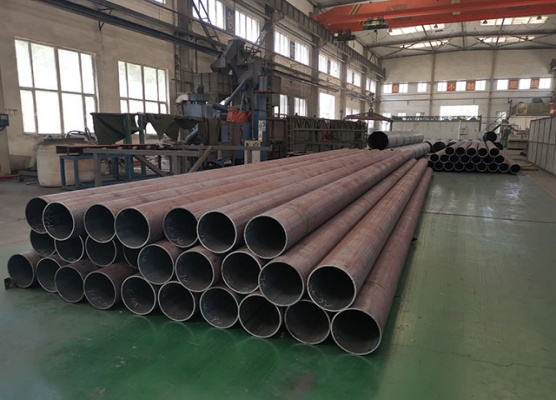

In our daily lives, the pipes we commonly encounter are mostly welded (like water pipes). However, in the extreme operating conditions of the industrial world, even the finest weld seam can become a critical point of failure. This is where seamless steel pipes, inherently uniform and without a seam, come into play. Their fundamental distinction from welded pipes lies in their “seamless” nature, which grants them superior structural strength, extremely high pressure-bearing capacity, and excellent fatigue resistance. So, in which critical scenarios are seamless pipes used? The following table will unveils the answers.

Seamless steel pipes are indispensable critical components across various high-demand industries due to their superior integrity and performance compared to welded pipes.

In the Energy Industry, their applications are fundamental. In Oil & Gas Exploration, they are used as well casing and tubing to support the well-wall and transport oil and gas from great depths, withstanding immense pressures and corrosive environments. During Refining & Petrochemical processes, seamless pipes form the essential process piping networks that safely transport high-temperature, high-pressure, and often flammable or toxic fluids. In Thermal Power Generation, they serve as the crucial “Four Major Pipes” within boilers, handling high-pressure steam. Furthermore, in Nuclear Power facilities, seamless steel pipes are specified for critical components within the nuclear island due to their utmost reliability and safety requirements.

The Mechanical Manufacturing & Transportation sector heavily relies on the strength and uniformity of seamless pipes. In Automotive Manufacturing, they are utilized for key dynamic components such as drive shafts and engine piston pins. The Aerospace industry employs them in highly demanding applications like aircraft landing gear actuators, engine fuel and hydraulic lines, and even rocket motor casings, where failure is not an option. For Hydraulic & Pneumatic Systems, seamless pipes are manufactured into hydraulic cylinder barrels and high-pressure tubing for construction machinery and machine tools, ensuring leak-free operation under extreme pressure cycles.

Beyond these primary sectors, seamless steel pipes are the material of choice for numerous other applications involving high temperature, high pressure service, and corrosive environments, wherever safety, reliability, and performance are paramount.