Here’s a detailed comparison of Q235B, Q345B, and Q345D steels, focusing on their properties, applications, and key differences:

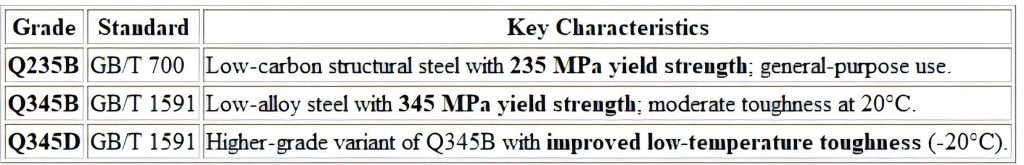

1. Overview

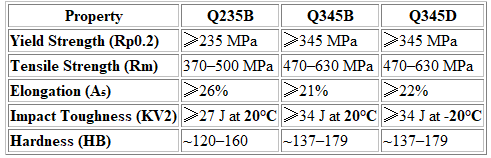

2. Mechanical Properties

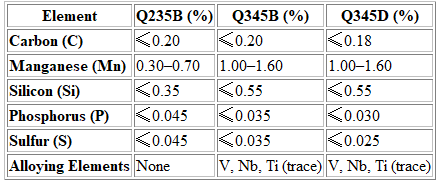

3. Chemical Composition

4. Key Differences

Q235B vs. Q345B

Strength: Q345B has ~50% higher yield strength than Q235B (345 MPa vs. 235 MPa).

Applications: Q235B: Non-critical structures (e.g., fences, brackets).

Q345B: Load-bearing structures (bridges, cranes, buildings).

Cost: Q235B is cheaper but weaker; Q345B offers better strength-to-cost ratio for heavy-duty use.

Q345B vs. Q345D

Impact Toughness: Q345B: Tested at 20°C (≥34 J).

Q345D: Tested at -20°C (≥34 J), making it suitable for cold climates.

Purity: Q345D has stricter limits on P and S (better weldability and ductility).

Applications: Q345B: General structural use in mild environments.

Q345D: Cold-region infrastructure (Arctic pipelines, offshore platforms).

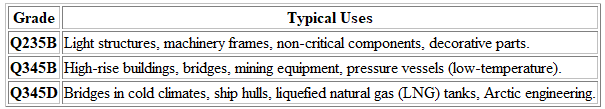

5. Applications

6. Fabrication Considerations

Welding: Q235B: Easy to weld with standard methods (no preheating required).

Q345B/Q345D: Require preheating (100–150°C) and low-hydrogen electrodes to avoid cracking.

Formability: Q235B is more ductile; Q345B/D need careful bending due to higher strength.

Corrosion: None are corrosion-resistant; coatings (e.g., galvanizing) are essential for harsh environments.

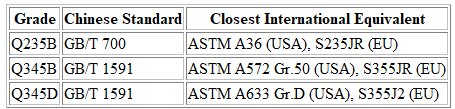

7. Standards and Equivalents

Conclusion

Choose Q235B for low-cost, non-critical applications.

Opt for Q345B for general high-strength structural projects.

Use Q345D in cold environments or where enhanced toughness is required (e.g., LNG tanks, Arctic infrastructure).

For critical applications, always verify material certifications (e.g., GB/T 1591 compliance) and perform impact testing for low-temperature use.