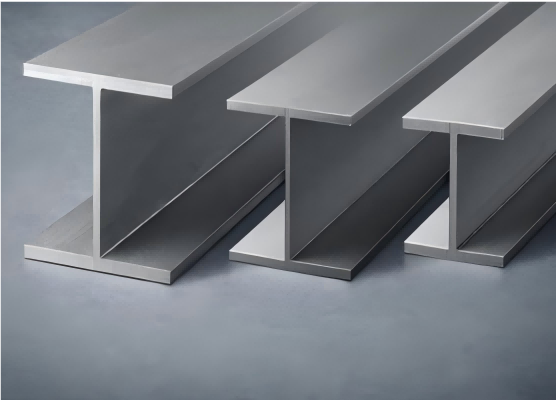

Baotou Steel has successfully supplied 2,000 tons of H-beams to Azerbaijan’s SOCAR for the construction of offshore platforms. The products, manufactured in accordance with EN 10025-2 S355J2, meet the specification 600*200*11*17 with R=22. The delivery followed an optimized logistics route: loaded directly from Baotou Steel’s warehouse onto rail transport to Tianjin Port, and then shipped via bulk carrier to Azerbaijan. This project marks a significant step in Baotou Steel’s expansion into the international energy infrastructure sector.

Baotou Steel Supplies SOCAR Project with Premium H-Beams

Project Challenge

This project presented multifaceted challenges that demanded precision engineering and flawless execution. The primary technical hurdle involved meeting the stringent mechanical properties of the EN 10025-2 S355J2 standard, which mandates superior toughness and weldability for structures enduring harsh marine environments. Achieving and maintaining the precise dimensional tolerances for the large, complex profile (600*200*11*17 with a specified fillet radius R=22) was critical to ensure seamless fit-up during platform assembly at the remote job site. Beyond production, ensuring the logistical integrity of the long steel products was paramount, as any handling damage during the extended inland-to-port transit could render the materials unfit for their critical application.

Our Solution

Baotou Steel delivered a comprehensive solution anchored in advanced engineering and optimized supply chain management. To meet the exacting technical specifications, our engineering team developed custom roll pass designs and optimized the entire rolling process. This dedicated approach guaranteed not only precise dimensional control and profile consistency but also the required internal metallurgical properties for the S355J2 grade. We enforced a rigorous, two-tier quality assurance protocol where every single beam underwent 100% dimensional inspection, and each production batch was subjected to full mechanical testing. On the logistics front, we implemented a streamlined "plant-to-port" strategy. The H-beams were loaded directly onto rail cars at our finished product warehouse and shipped to the dedicated berth at Tianjin Port, minimizing domestic handling to a single lift. This method significantly reduced the risk of transit damage and guaranteed the products arrived in pristine condition for their sea voyage to Azerbaijan. Through this integrated approach, Baotou Steel ensured the on-time delivery of high-integrity structural components and demonstrating our commitment to executing complex, high-stakes international projects.

Related products

EN10025 S235JR H-Beam Steel

Read More

API 5CT L80-1 Casing for Deep Wells

Read More

API 5CT J55 Oil Casing Pipe Size 4.5″to 20″

Read More

APL 5L X52 Oil and Gas Pipeline

Read More

EN10025 S275JR H-Beam Steel

Read More

API 5CT K55 Tubing With LC Thread Connection

Read More

Grade P91 ASTM A335 Seamless Alloy Steel Pipe

Read More

ASTM A53 10# Steel Structure Tube

Read More