R65 rail pads are essential components use with UIC R65 rails (standard rail profile with a height of ~172mm) to secure rails to sleepers (concrete or wooden), maintain gauge stability, absorb vibrations, and adjust track geometry.

- Fittings

R65 Rail Pads

Email:

sales@imristeel.com

Phone:

+86 13646172523

Quote Now

Product Detail

Packaging & Delivery

Related Products

Product Details

| Item | Specification | Standard/Notes |

| Material | Cast Steel(ZG230-450/ZG270-500) | EN 15689/ASTM A148 |

| Hardness | 120-160 HB | Brinell Hardness Test |

| Tensile Strength | ≥450 MPa | UIC 860-1/EN10025 |

| Yield Strength | ≥230 MPa | |

| Thickness | 12-15 mm | |

| Width | 1 50-160 mm | Matches R65 rail base |

| Length | 180-200 mm | |

| Rail lnclination | 1:40 slope | |

| Bolt Holes | 2-4 holes(018-22 mm) | |

| Surface Treatment | Hot-dip galvanized(≥80μm) | IS0 1461/Corrosion resistance |

| Load Capacity | Dynamic:50-100 kN/mm(under UIC loading) | Tested per EN 13146-5 |

| 0perating Temp. | -40”C to+70°C | |

| Lifespan | 15-20 years (standard conditions) |

Chemical Component

| Element | Composition (%) | Standard Reference |

| Carbon(C) | 0.20-0.30 | EN15689/ASTM A148 |

| Silicon(Si) | 0.20-0.50 | |

| Manganese(Mn) | 0.50-1.20 | |

| Phosphorus(P) | ≤0.035 | |

| Sulfur(s) | ≤0.035 | |

| Chromium(Cr) | ≤0.30(optional) | For enhanced hardness |

| Nickel(Ni) | ≤0.30(optional) | For low-temp toughness |

Mechanical Properties

| Property | Value | Test Standard |

| Tensile Strength | ≥450 MPa | IS0 6892-1/ASTME8 |

| Yield Strength(Rp0.2) | ≥230 MPa | |

| Elongation at Break | ≥18% | |

| Hardness(Brinell) | 120-160 HB | IS0 6506-1 |

| Impact Toughness(Charpy) | ≥27 J(-20°C) | IS0 148-1 |

| Fatigue Limit(1 07cycles) | 250-300 MPa | UIC 860-1 |

Additional Performance Data

| Parameter | Specification |

| Dynamic Stiffness | 50-100 kN/mm(UIC loading) |

| Corrosion Resistance | ≥1,000 hrs(Salt Spray Test) |

| Thermal Stability | -40°C to+70°C(NO.cracking) |

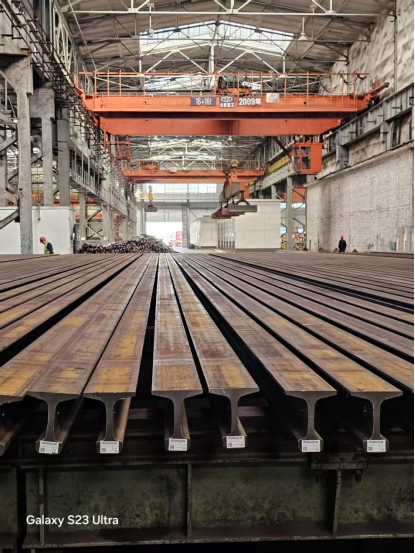

Packaging & Delivery

Packaging & Delivery

· Packaging Details: Use 7mm corrugated boxes or wooden crates (for export), filled with cushioning material (e.g., foam).

· Port: Tianjin Port

· Lead Time: Within 20-30 days depends on the order quantity

Packaging & Shipping

· Minimum order quantity: 50 tons

· Price: FOB at Xin’gang port in Tianjin

· Payment: 30% deposit in advance, the balance against the copy of B/L; or 100% L/C, etc

· Lead Time: within 10-25 workdays normally

· Packing: Standard seaworthy packing or as per your request .(as pictures)

· Sample: Free sample is available.

· Price: FOB at Xin’gang port in Tianjin

· Payment: 30% deposit in advance, the balance against the copy of B/L; or 100% L/C, etc

· Lead Time: within 10-25 workdays normally

· Packing: Standard seaworthy packing or as per your request .(as pictures)

· Sample: Free sample is available.

Related products

Global Rail Supplier|Heavy Rail/Crane/High Speed Railway (EN13674-1, GOST51685)

Read More

GB/T 17396 27SiMn hydraulic pillar pipe

Read More

Corrosion Resistant API 5CT L80-1 Tubing

Read More

GB/T 18248 35CrMo Gas Cylinder Tube

Read More

34CrMo4 Gas Cylinder Tube

Read More

API 5L X65Q Seamless Pipeline for Sour Service

Read More

GB/T 5310-2017 15CrMoG Seamless Alloy Steel Pipe

Read More

OCTG API 5CT J55 Oil Well Tubing

Read More