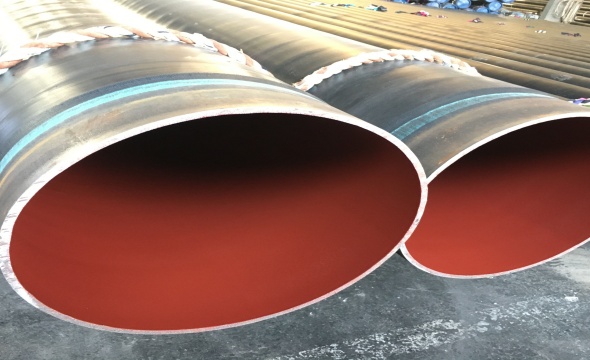

Liquid Epoxy Coating is a high-performance, protective coating for the internal and external surfaces of steel pipes. It consists of an epoxy resin and a curing agent that, when mixed, undergo a chemical reaction to form a tough, seamless, and chemically resistant barrier. It effectively isolates various corrosive media such as water, acids, alkalis, salts, and petroleum products, significantly extending the service life of pipelines and ensuring the purity of the conveyed medium. Liquid Epoxy Coating is widely use in oil & gas, water, and chemical industries.

- Coating Pipeline, Liquid Epoxy Coating

Liquid Epoxy Coating

Email:

sales@imristeel.com

Phone:

+86 13646172523

Quote Now

Product Detail

Performance Requirements

Related Products

Product Detail

Product Name:

Liquid Epoxy Coating

Standard:

API RP 5L2 ,AWWA C 210

Grade:

General-purpose Type, Pipeline-specific Type (inner/outer coating)

Thickness:

Internal: 250-500μm; External: 300-1000μm (Adjustable)

Shape:

Liquid

Outer Diameter:

Ф114.3 – 406 mm

Place of Origin:

Inner Mongolia, China

Usage:

Oil & Gas Pipelines, Potable Water Pipelines, Chemical Pipelines, Fire Protection Pipelines

Surface Treatment:

Blast cleaning to Sa 2.5

Tolerance:

According to relevant coating standards

End:

Plain

End Protector:

HDPE crash cap or customized

length:

R1, R2, R3

Brand:

Baotou steel

Delivery Time:

Normally within 30-45 days and according to the quantity.

Performance Requirements

| Item | Specification |

| Salt Spray Resistance | ≥1000 hours, no rust/blistering (NSS test) |

| Acid Resistance | 10% H₂SO₄, 168h: No blistering/peeling, adhesion loss ≤20% |

| Alkali Resistance | 10% NaOH, 168h: No discoloration/peeling |

| Adhesion (Pull-off) | ≥8 MPa (on steel substrate, Sa 2.5 blast cleaning) |

| Hardness | ≥80 Shore D |

| Impact Resistance | ≥50 cm·kg (no cracking/peeling) |

| VOC Content | ≤50 g/L (solvent-free type) |

| Heat Resistance | Continuous use: -40°C ~ 120°C |

Related products

POM Raw Material Injection Grade for Mechanical Parts

Read More

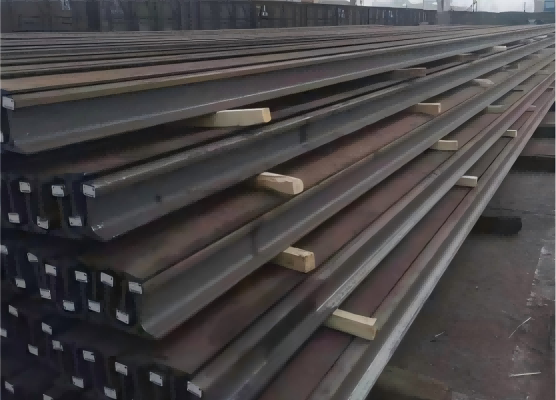

Heavy Rail of 60E1/UIC60 rails

Read More

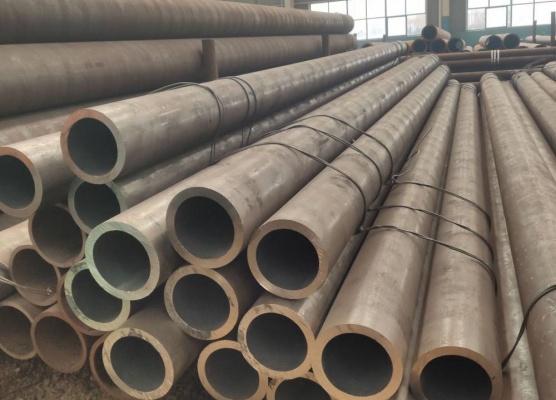

GB/T 8162-2018 27SiMn Alloy Structural Steel Tube

Read More

APL 5L X65 Oil and Gas Pipeline

Read More

Premium R350HT P65 Heat-Treated Steel Rail

Read More

GB/T 8162-2018 20# Class Steel Tube Structure

Read More

APL 5L X42 Oil and Gas Pipeline

Read More

API 5L Seamless Pipeline Tube X42-X70 PSL2

Read More