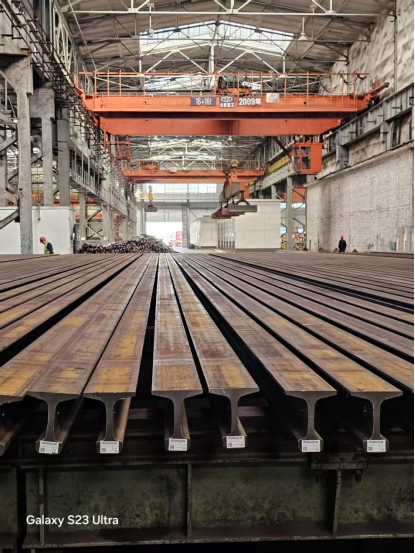

IMRI supplies rails of R260/R350HT material, covering a full range of products such as American Standard 115RE, European Standard 60E1, Russian Standard P65, etc., which are suitable for heavy-duty transportation, high-speed railroads and mining scenarios, and are certified by SGS/ISO9001.

- Rail & Fittings, Steel Rail

Global Rail Supplier|Heavy Rail/Crane/High Speed Railway (EN13674-1, GOST51685)

Email:

sales@imristeel.com

Phone:

+86 13646172523

Quote Now

Product Details

Packaging & Delivery

Related Products

Core Advantages and Technical Standards

Military-grade hot rolling process Adopting vacuum degassing technology to eliminate cracks inside the rails, ensuring compressive strength through ultrasonic flaw detection and hardness testing, meeting EN/UIC/AREMA/GOST standards for wear resistance index, and adapting to extreme environments ranging from -40℃ to 70℃.Multi-scenario application coverage

Heavy railway track: 75kg/m, 60kg/m and other high stress rails, suitable for high-speed rail and freight lines.

Crane rail: DIN standard rails such as QU120, QU100, etc., with load capacity up to 150 tons/axle.Rail structure design and performance parameters

Optimized design of I-section

rail head: curved contact surface reduces wheel-rail friction coefficient (μ≤0.35)

rail waist: thickness ≥16.5mm, enhancing transverse shear resistance

rail bottom: width ≥150mm, disperses the pressure of rail bed by 30%.Why choose IMRI rails?20 years of experience in supplying railroad projects in 30+ countries worldwide.

Full process quality control: 12 inspection procedures from steel making to straightening, defect rate <0.02%.

Military-grade hot rolling process Adopting vacuum degassing technology to eliminate cracks inside the rails, ensuring compressive strength through ultrasonic flaw detection and hardness testing, meeting EN/UIC/AREMA/GOST standards for wear resistance index, and adapting to extreme environments ranging from -40℃ to 70℃.Multi-scenario application coverage

Heavy railway track: 75kg/m, 60kg/m and other high stress rails, suitable for high-speed rail and freight lines.

Crane rail: DIN standard rails such as QU120, QU100, etc., with load capacity up to 150 tons/axle.Rail structure design and performance parameters

Optimized design of I-section

rail head: curved contact surface reduces wheel-rail friction coefficient (μ≤0.35)

rail waist: thickness ≥16.5mm, enhancing transverse shear resistance

rail bottom: width ≥150mm, disperses the pressure of rail bed by 30%.Why choose IMRI rails?20 years of experience in supplying railroad projects in 30+ countries worldwide.

Full process quality control: 12 inspection procedures from steel making to straightening, defect rate <0.02%.

Core Advantages and Technical Standards

Military-grade hot rolling process Adopting vacuum degassing technology to eliminate cracks inside the rails, ensuring compressive strength through ultrasonic flaw detection and hardness testing, meeting EN/UIC/AREMA/GOST standards for wear resistance index, and adapting to extreme environments ranging from -40℃ to 70℃.

Multi-scenario application coverage

Heavy railway track: 75kg/m, 60kg/m and other high stress rails, suitable for high-speed rail and freight lines.

Crane rail: DIN standard rails such as QU120, QU100, etc., with load capacity up to 150 tons/axle.

Rail structure design and performance parameters

Optimized design of I-section

rail head: curved contact surface reduces wheel-rail friction coefficient (μ≤0.35)

rail waist: thickness ≥16.5mm, enhancing transverse shear resistance

rail bottom: width ≥150mm, disperses the pressure of rail bed by 30%.

Steel Rails-Hot Standards from Baotou steel:

| Standard | Sepc. | Material Typical Grade |

| UIC860 | UIC54 | 700,900A,900B |

| UIC60 | ||

| EN13674.1 | 50E1 | R200,R350HT,R260Mn,R35LHT,R320Cr,R370CrHT |

| 54E1 | ||

| 60E1 | ||

| 60E2 | ||

| R50 | ||

| R65 | ||

| BS-11-1985 | BS80A | 700,900A,900B |

| BS90A | ||

| BS100A | ||

| AREMA | 115RE | SS,HH,LA,IH |

| 136RE | ||

| ASCE60 | U71Mn | |

| ASCE85 | U71Mn | |

| GB 2585-2007 | 50kg/m | U71Mn U75V |

| 60kg/m | ||

| 75kg/m | ||

| TB/T2344-2012 | 50kg/m | U71Mn,U75V,U77MnCr U78CrV |

| 60kg/m | ||

| 75kg/m | ||

| EN14811 | 59R2 | R200,R350HT,R260Mn,R35LHT,R320Cr,R370CrHT |

| 60R1 | ||

| GB 11264-1989 | 15kg/m | 55Q, Q235 |

| 18kg/m | 55Q, Q235 | |

| 22kg/m | 55Q, Q235 | |

| 24kg/m | 55Q, Q235 | |

| 30kg/m | 55Q, Q235 | |

| 38kg/m | 50Mn, U71Mn | |

| 43kg/m | 50Mn, U71Mn | |

| GB Crane rails | QU70 | U71Mn |

| QU80 | U71Mn | |

| QU100 | U71Mn | |

| QU120 | U71Mn |

Chemical Composition of Chinese Standard(%):

| Chemical Composition of Chinese Standard(%) | ||||||

| Grade | C | Si | Mn | Max | V | |

| P | S | |||||

| Q235 | 0.12~0.20 | ≤0.3 | 0.3~0.7 | 0.045 | 0.045 | - |

| Q345 | ≤0.20 | ≤0.55 | 1.00-1.60 | 0.040 | 0.04 | - |

| 20MnK | 0.15-0.26 | 0.20-0.60 | 1.20-1.60 | 0.050 | 0.050 | - |

| M540 | 0.20-0.29 | 0.17-0.37 | 1.60-1.80 | 0.045 | 0.045 | - |

| 50Mn | 0.48-0.56 | 0.17-0.37 | 0.70-1.00 | 0.035 | 0.035 | - |

| 55Q | 0.50-0.60 | 0.15-0.35 | 0.60-0.90 | 0.045 | 0.045 | - |

| U71Mn | 0.65-0.76 | 0.15-0.35 | 1.10-1.40 | 0.040 | 0.040 | - |

| U75v | 0.71-0.80 | 0.50-0.80 | 0.70-1.05 | 0.030 | 0.030 | 0.04-0.12 |

| 900A | 0.60-0.80 | 0.10-0.50 | 0.80-1.30 | 0.040 | 0.040 | - |

| R260 | 0.60-0.82 | 0.13-0.60 | 0.65-1.25 | 0.030 | 0.030 | - |

| R350H | 0.70-0.82 | 0.13-0.60 | 0.60-1.25 | 0.025 | 0.025 | - |

| ASSZ-1 | 0.76-0.82 | 0.10-0.50 | 0.90-1.15 | 0.030 | 0.030 | - |

Mechanical Properties of Chinese Standard:

| Grade | Yield strength (Mpa) | Tensile strength (Mpa) | Elongation (%) | Hardness (%) |

| Q235 | ≥235 | 375-460 | ≥26 | - |

| Q345 | ≥345 | 470-630 | ≥21 | - |

| 20MnK | ≥355 | ≥510 | ≥18 | - |

| M540 | ≥390 | ≥540 | ≥18 | - |

| 50Mn | - | ≥645 | ≥13 | - |

| 55Q | - | ≥685 | - | ≥197 |

| U71Mn | - | ≥880 | ≥9 | 240-270 |

| U75v | - | ≥980 | ≥9 | 240-270 |

| 900A | - | ≥880 | ≥10 | 240-270 |

| R260 | - | ≥880 | ≥10 | 260-300 |

| R350HT | - | ≥1175 | ≥9 | 350-390 |

| ASSZ-1 | - | ≥980 | ≥9 | ≥275 |

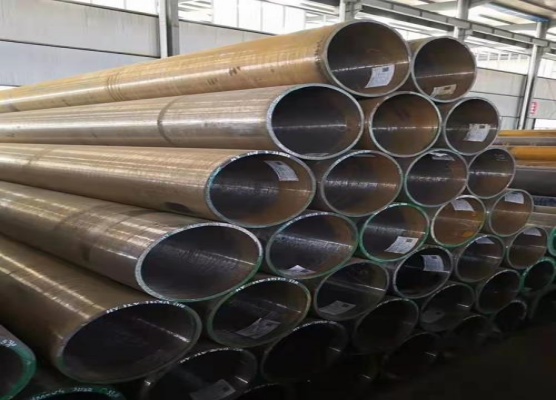

Packaging & Delivery

Packaging & Delivery

· Packaging Details: Bundles wrapped with strong steel trips, caps on two ends of every pipe or according to customers’ requirements.

· Port: Tianjin Port

· Lead Time: Within 20-30 days depends on the order quantit

Packaging & Shipping

· Minimum order quantity: 5 tons

· Price: FOB or CIF or CFR at Xin’gang port in Tianjin

· Payment: 30% deposit in advance, the balance against the copy of B/L; or 100% L/C, etc

· Lead Time: within 10-25 workdays normally

· Packing: Standard seaworthy packing or as per your request .(as pictures)

· Sample: Free sample is available.

Related products

APL 5L X65 Oil and Gas Pipeline

Read More

Heavy Rail of 54E1/UIC54 Rails

Read More

Heavy Rail of 60E1/UIC60 rails

Read More

OCTG Casing API 5CT K55 Oil Gas Pipe

Read More

R65 Rail Pads

Read More

34CrMo4 Gas Cylinder Tube

Read More

API 5L X56Q Seamless Pipe for Oil Well Drilling

Read More

API 5L X60Q Oil Gas Seamless Pipeline

Read More