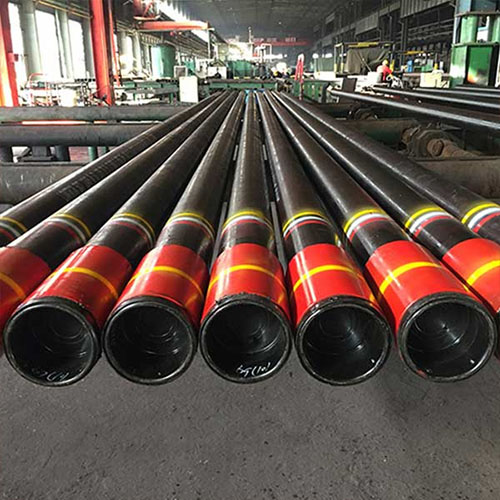

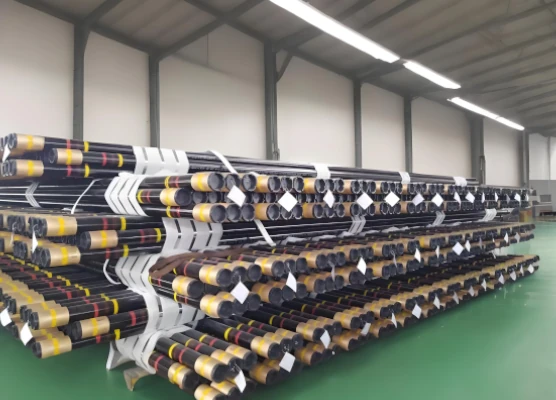

The Dual Powder System (DPS) pipeline coating is an advanced, two-layer fusion-bonded epoxy (FBE) solution. It combines a corrosion-resistant base layer with a tough, flexible outer layer. This design provides superior mechanical protection, abrasion resistance, and enhanced durability, making it ideal for challenging environments like directional drilling, rocky terrains, and offshore applications.

- Coating Pipeline, FBE & DPS

Dual Powder System(DPS) Pipeline Coating

Email:

sales@imristeel.com

Phone:

+86 13646172523

Quote Now

Product Detail

Chemical Component

Related Products

Product Detail

Product Name:

Dual Powder System(DPS) Pipeline Coating

Standard:

CAN/CSA Z245.20; ISO 21809-2

Grade:

/

Thickness:

Double-layer 450-1000μm

Shape:

Round

Outer Diameter:

Ф114.3 – 406 mm

Place of Origin:

Inner Mongolia, China

Usage:

Harsh soil conditions, such as areas with gravel, rocks, and permafrost regions

Surface Treatment:

Hot Rolled

Tolerance:

WT: -12.5%

End:

Plain

End Protector:

HDPE crash cap or customized

length:

R1, R2, R3

Brand:

Baotou steel

Delivery Time:

Normally within 30-45 days and according to the quantity.

Production test requirements-Acceptance criteria

| Production test requirements-Acceptance criteria | ||

| Test item | – | Standard |

| Cure-∆Tg | ≤5℃ | CSA Z245.20 |

| 24h cathodic disbondment at 65℃ | ≤11.5mm | |

| Interface contamination | ≤30% | |

| Cross-section porosity | Rating of 1-4 | |

| Interface porosity | Rating of 1-4 | |

| 1.5℃ flexibility | No cracking | |

| 3.0J impact resistance | No holidays | |

| 24h adhesion at 75℃ | Rating of 1-3 | |

| Surface roughness | >50μm | |

| Performance | ||

| Test item | Acceptable indicators | Standard |

| Curing time | Meet the specified indicators of the manufacturer | CSA Z245.20 |

| Gel time | Meet the specified indicators of the manufacturer | |

| Humidity Ratio | Meet the specified indicators of the manufacturer | |

| Particle size distribution | Meet the specified indicators of the manufacturer | |

| Density | Meet the requirements of the manufacturer, Within 50g/L | |

| Thermal characteristics | Meet the requirements of the manufacturer | |

Related products

API 5L X52Q Oil Pipeline for Corrosion Resistance

Read More

ASTM A53 10# Steel Structure Tube

Read More

Grade P12 ASTM A335 Chromium-Molybdenum Alloy Pipe

Read More

GB/T 3077-2015 20Cr Seamless Alloy Steel Pipe

Read More

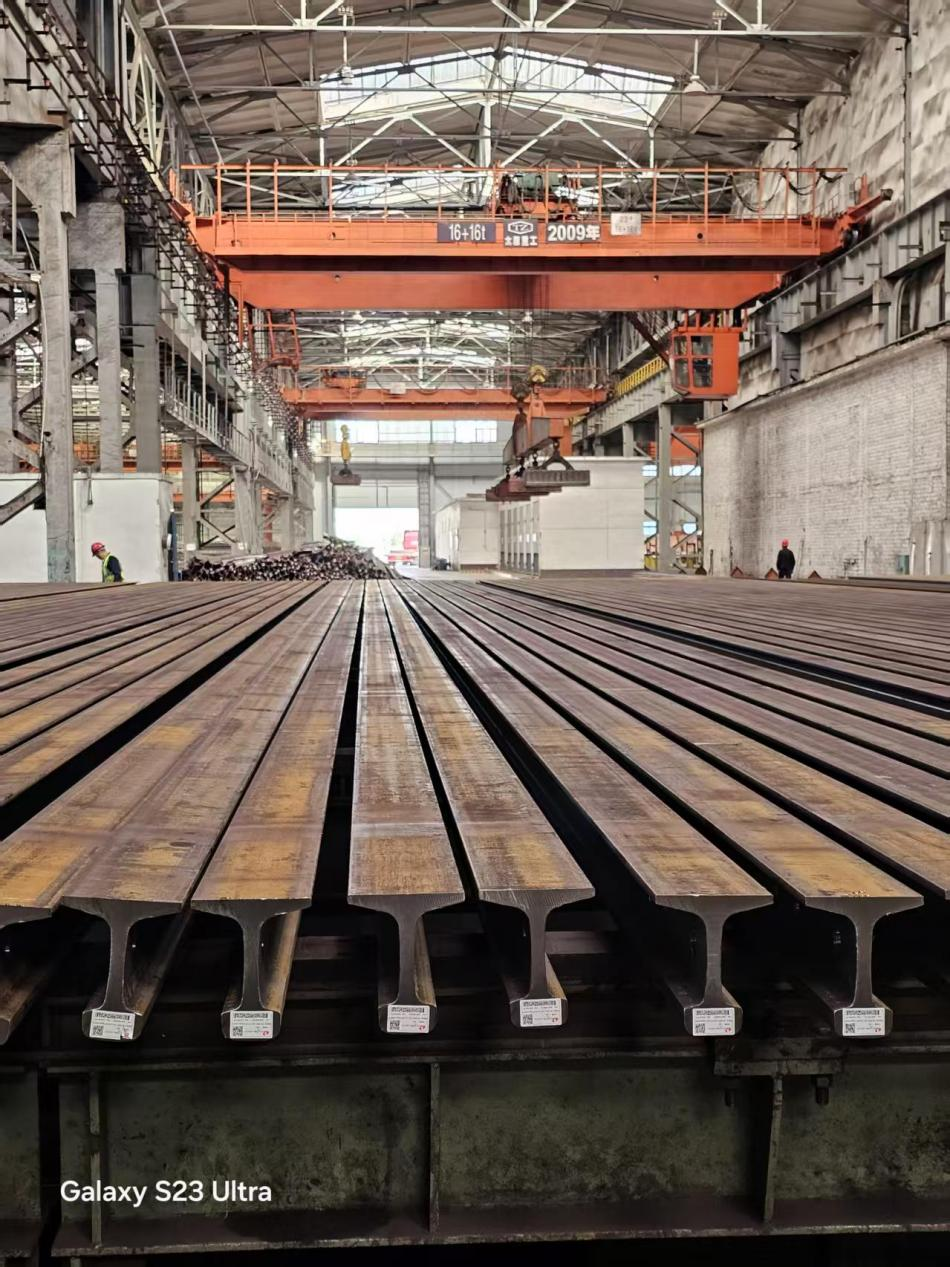

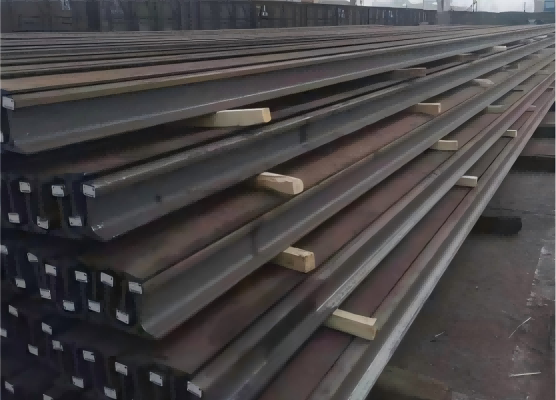

Heavy Rail of P50/R50 Rails

Read More

API 5CT N80-1 Tubing Pipe With LTC Thread

Read More

API 5CT 13% Chromium L80 Tubing

Read More

Premium R350HT P65 Heat-Treated Steel Rail

Read More