IMRI ASTM A53 structural tube combine weldability (≤0.05% sulfur) with 345MPa yield strength (20% stronger than standard carbon tubes). Key features include Seam Integrity; Dimensional Accuracy; Corrosion Options.

- Structural tube

ASTM A53 Q345B Structural Steel Tube

Email:

sales@imristeel.com

Phone:

+86 13646172523

Quote Now

Product Detail

Packaging & Delivery

Related Products

Product Detail

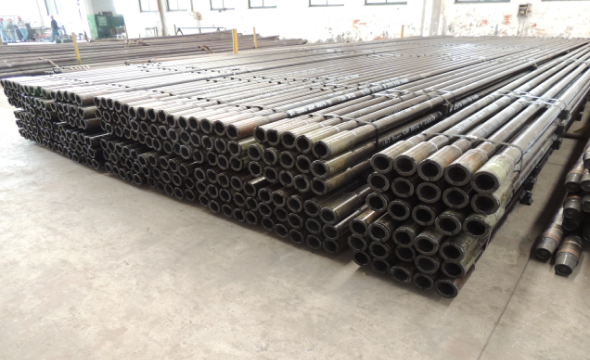

Structural Tube, Seamless Steel Tubes For Structural Purposes is made by heating a high-grade carbon steel billet to a suitably high temperature and then entering a hot rolling mill. This process refines the internal structure and improves strength and toughness for a wide range of applications.

Quick Details

Standard:

GB/T 8162 ASTM A53 EN10210 JIS G 3444

Grade:

Q345B

Thickness:

2.9-60mm

Section shape:

Round

Outer Diameter:

Ф38-457

Place of origin:

Baotou, China(Mainland)

Function:

High-efficiency bearing

Technique:

Hot Rolled, Seamless

Certification:

GB/T 8162 ASTM A53 EN10210 JIS G 3444

Surface Treatmen:

According to customers request

Alloy Or Not:

No

length:

1-12m

Supply Ability:

( 180.0000 )Ton/Tons per year

End:

Bevel; plain

Application:

Construction engineering; Mechanical manufacturing

Brand:

Baotou steel

Cross-sectional type:

Circular/Square/Rectangular

Dimensional accuracy:

OD tolerance ±0.5%, WT tolerance ±10%

Size and specification

| DN | OD | WT | |||||||||||||||

| Inch | mm | SCH5S | SCH10S | SCH10 | SCH20 | SCH30 | SCH40 | SCH60 | SCH80 | SCH100 | SCH120 | SCH140 | SCH160 | Sth | XS | XXS | |

| 50 | 2″ | 60.3 | 1.65 | 2.77 | – | – | – | 3.91 | – | 5.54 | – | – | – | 8.74 | 3.91 | 5.54 | 11.07 |

| 65 | 2 1/2″ | 73 | 2.11 | 3.05 | – | – | – | 5.16 | – | 7.01 | – | – | – | 9.53 | 5.16 | 7.01 | 14.02 |

| 80 | 3″ | 88.9 | 2.11 | 3.05 | – | – | – | 5.49 | – | 7.62 | – | – | – | 11.13 | 5.49 | 7.52 | 15.24 |

| 90 | 3 1/2″ | 101.6 | 2.11 | 3.05 | – | – | – | 5.74 | – | 8.08 | – | – | – | – | 5.74 | 8.08 | – |

| 100 | 4″ | 114.3 | 2.11 | 3.05 | – | – | – | 6.02 | – | 8.58 | – | 11.13 | – | 13.49 | 6.02 | 8.56 | 17.12 |

| 125 | 5″ | 141.3 | 2.77 | 3.4 | – | – | – | 6.55 | – | 9.53 | – | 12.7 | – | 15.88 | 6.55 | 9.53 | 18.05 |

| 150 | 6″ | 168.3 | 2.77 | 3.4 | – | – | – | 7.11 | – | 10.97 | – | 14.27 | – | 18.26 | 7.11 | 10.97 | 21.95 |

| 200 | 8″ | 219.1 | 2.77 | 3.76 | – | 6.35 | 7.04 | 8.18 | 10.31 | 12.7 | 15.09 | 18.26 | 20.62 | 23.01 | 8.18 | 12.7 | 22.23 |

| 250 | 10″ | 273.1 | 3.4 | 4.19 | – | 6.35 | 7.8 | 9.27 | 12.7 | 15.09 | 18.26 | 21.44 | 25.4 | 28.58 | 9.27 | 12.7 | 25.4 |

| 300 | 12″ | 323.9 | 3.96 | 4.57 | – | 6.35 | 8.38 | 10.31 | 14.27 | 17.48 | 21.44 | 25.4 | 28.58 | 33.32 | 9.53 | 12.7 | 25.4 |

| 350 | 14″ | 355.5 | 3.96 | 4.78 | 6.35 | 7.92 | 9.53 | 11.13 | 15.09 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | 9.53 | 12.7 | – |

| 400 | 16″ | 406.4 | 4.19 | 4.78 | 6.35 | 7.92 | 9.53 | 12.7 | 16.66 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | 9.53 | 12.7 | – |

| 450 | 18″ | 457.2 | 4.19 | 4.78 | 6.35 | 7.92 | 11.13 | 14.27 | 19.05 | 23.83 | 39.36 | 34.93 | 39.67 | 45.24 | – | – | – |

| 500 | 20″ | 508 | 4.78 | 5.54 | 6.35 | 9.53 | 12.7 | 15.09 | 20.62 | 26.19 | 32.54 | 38.1 | 44.45 | 50.01 | – | – | – |

| 550 | 22″ | 558.8 | 4.78 | 5.54 | 6.35 | 9.53 | 12.7 | – | 22.23 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | – | – | – |

| 600 | 24″ | 609.6 | 5.54 | 6.35 | 6.35 | 9.53 | 14.27 | 17.48 | 24.61 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | – | – | – |

Chemistry Component

| Grade | C | Si | Mn | P | S | Nb | V | Ti | Cr | Ni | Cu | N | Mo | B | Als |

| Not more than | Not less than | ||||||||||||||

| Q345 A | 0.20 |

0.50 |

1.70 | 0.035 | 0.035 | – | – | – |

0.30 |

0.50 |

0.20 |

0.012 |

0.10 |

– | – |

| Q345 B | 0.035 | 0.035 | |||||||||||||

| Q345 C | 0.030 | 0.030 | 0.07 | 0.15 | 0.20 | 0.015 | |||||||||

| Q345 D | 0.18 | 0.030 | 0.025 | ||||||||||||

| Q345 E | 0.025 | 0.020 | |||||||||||||

| Q390 A |

0.20 |

0.50 |

1.70 | 0.035 | 0.035 |

0.07 |

0.20 |

0.20 |

0.30 |

0.50 |

0.20 |

0.015 |

0.10 |

– | – |

| Q390 B | 0.035 | 0.035 | |||||||||||||

| Q390 C | 0.030 | 0.030 | 0.015 | ||||||||||||

| Q390 D | 0.030 | 0.025 | |||||||||||||

| Q390 E | 0.025 | 0.020 | |||||||||||||

| Q420 A |

0.20 |

0.50 |

1.70 | 0.035 | 0.035 |

0.07 |

0.20 |

0.20 |

0.30 |

0.80 |

0.20 |

0.015 |

0.20 |

– | – |

| Q420 B | 0.035 | 0.035 | |||||||||||||

| Q420 C | 0.030 | 0.030 | 0.015 | ||||||||||||

| Q420 D | 0.030 | 0.025 | |||||||||||||

| Q420 E | 0.025 | 0.020 | |||||||||||||

Tensile test requirements

| Steel grade | Tensile strength Rm/MPa | Lower yield strength ReL a/MPa | Elongation after breakingb A% | ||||

| Nominal wallthickness S/mm | |||||||

| ≤16 | >16~30 | >30 | |||||

| Not less than | |||||||

| Q345 A |

470~630 |

345 |

325 |

295 | 20 | ||

| Q345 B | |||||||

| Q345 C | 21 | ||||||

| Q345 D | |||||||

| Q345 E | |||||||

| Q390 A |

490~650 |

390 |

370 |

350 | 18 | ||

| Q390 B | |||||||

| Q390 C | 19 | ||||||

| Q390 D | |||||||

| Q390 E | |||||||

| Q420 A |

520~680 |

420 |

400 |

380 | 18 | ||

| Q420 B | |||||||

| Q420 C | 19 | ||||||

| Q420 D | |||||||

| Q420 E | |||||||

Packaging & Delivery

Packaging & Delivery

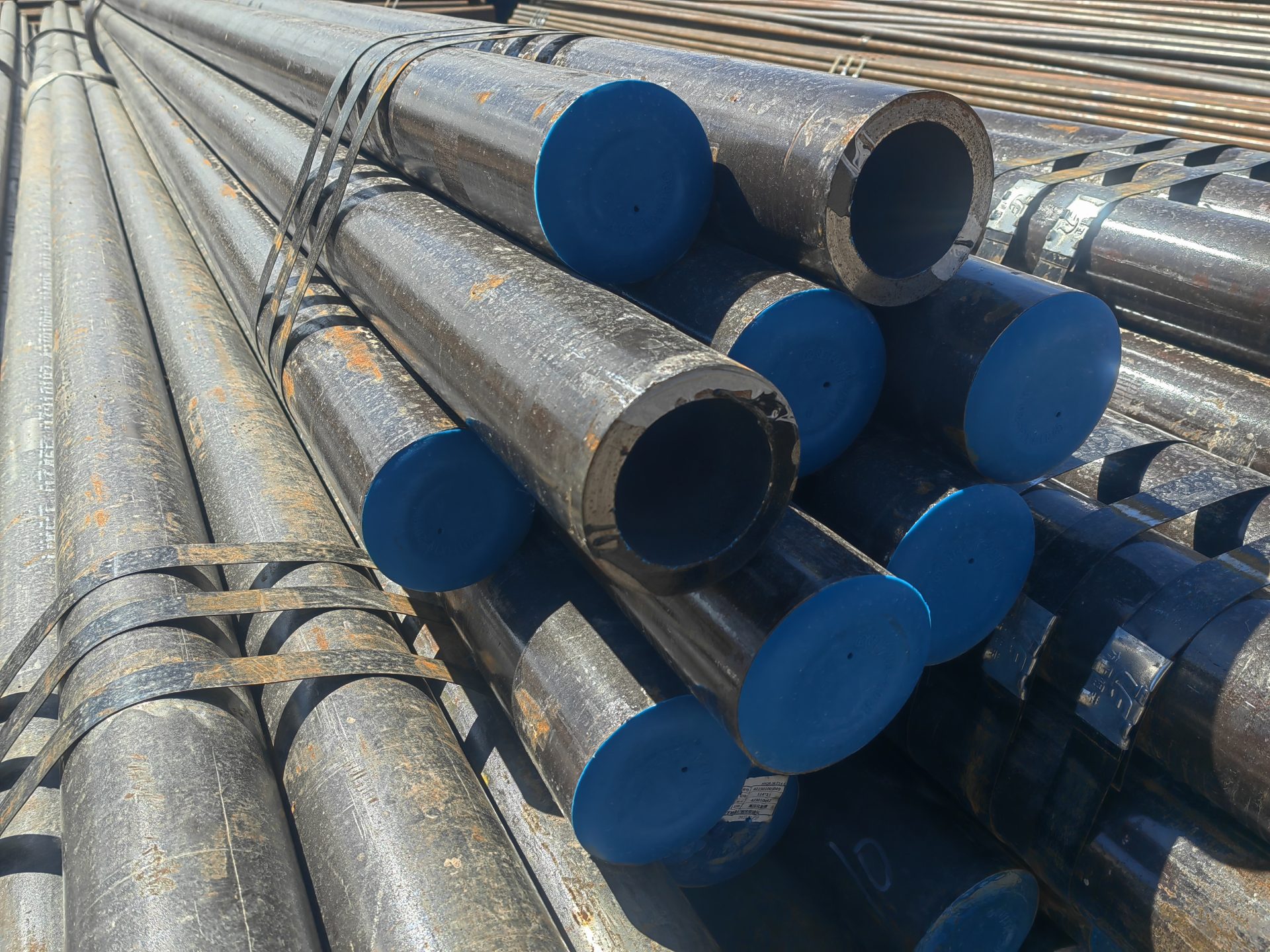

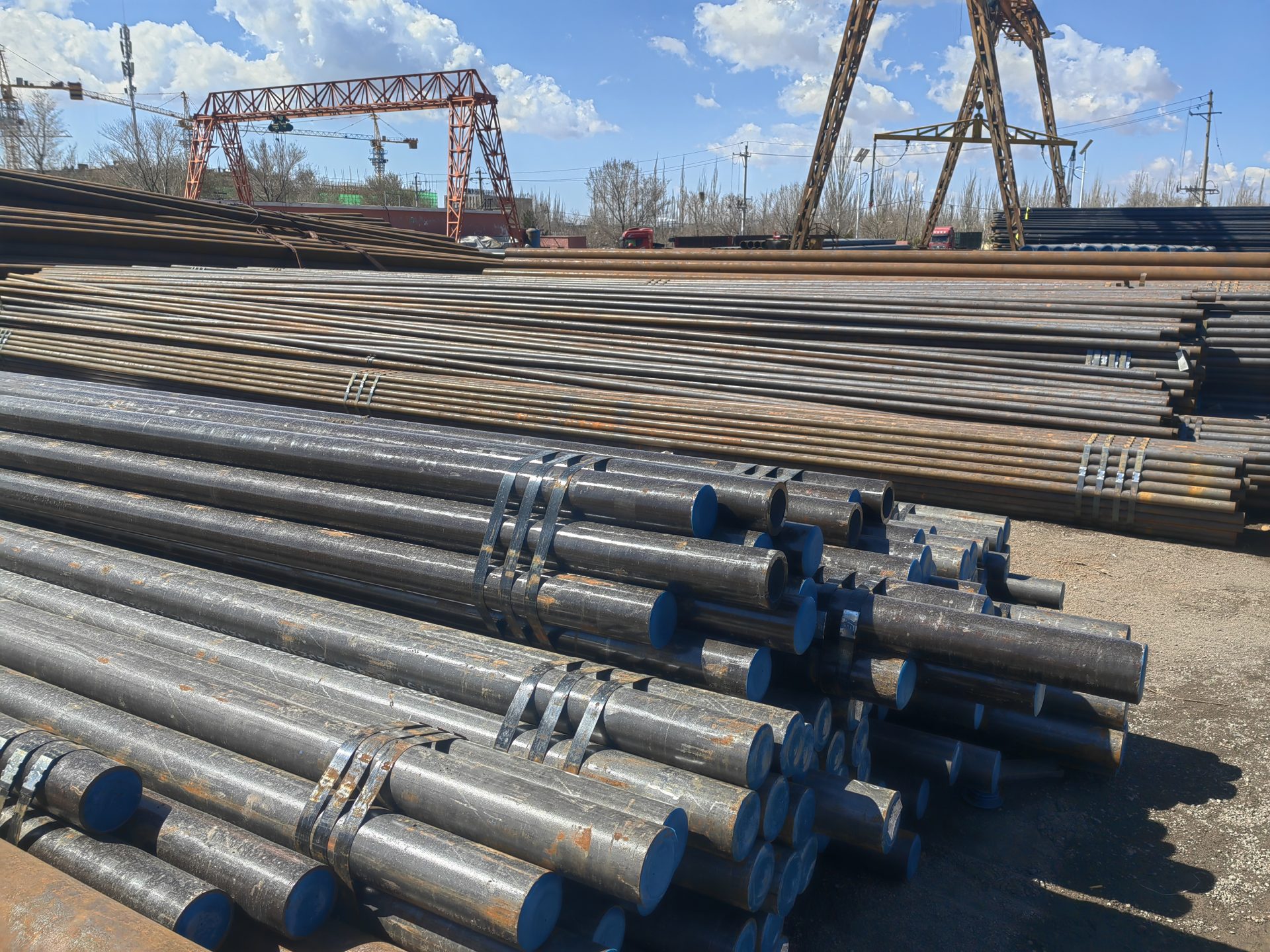

· Pipe End: Covered HDPE crash cap

· Packing: The steel straps are bundled into hexagonal or rectangular shapes. The number of steel straps bundled varies for different specifications

· Quality control: Provide complete quality traceability documents

· Packing: The steel straps are bundled into hexagonal or rectangular shapes. The number of steel straps bundled varies for different specifications

· Quality control: Provide complete quality traceability documents

Packaging & Shipping

· Minimum order quantity: 5 tons

· Price: FOB at Xin’gang port in Tianjin or CIF or CFR

· Payment: 30% deposit in advance, the balance against the copy of B/L; or 100% L/C, etc

· Lead Time: within 10-25 workdays normally

· Sample: Free sample is available.

· Price: FOB at Xin’gang port in Tianjin or CIF or CFR

· Payment: 30% deposit in advance, the balance against the copy of B/L; or 100% L/C, etc

· Lead Time: within 10-25 workdays normally

· Sample: Free sample is available.

Quality inspection

Related products

GB/T 18248 42CrMo Gas Cylinder Tube

Read More

GB/T 3077-2015 High-Strength Seamless Steel Pipe 42CrMo

Read More

Heavy Rail of 60E1/UIC60 rails

Read More

API 5L X46Q Pipeline Large Diameter

Read More

GB/T 8162-2018 16Mn Alloy Seamless Structure Tube

Read More

Dual Powder System(DPS) Pipeline Coating

Read More

R65 Rail Pads

Read More

GB/T 17396 30MnNbRE hydraulic pillar pipe

Read More