IMRI’s K55 tubing, made of high strength carbon steel, meets the strict API 5CT standard. With a yield strength of 379 ~ 552 MPa, it can withstand high pressure oil well environments.

- Tubing

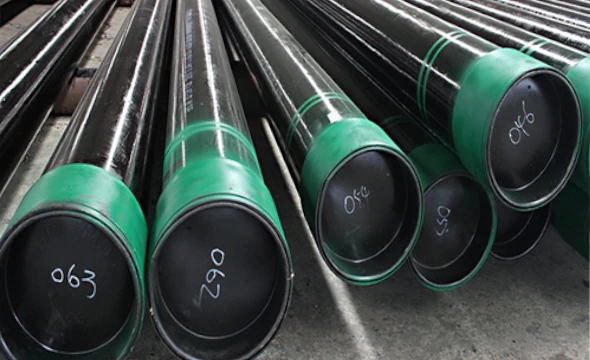

API 5CT K55 Tubing With LC Thread Connection

Email:

sales@imristeel.com

Phone:

+86 13646172523

Quote Now

Product Detail

Chemical Component

Related Products

Product Detail

Product Name:

API 5CT K55 Tubing With LC Thread Connection

Standard:

API 5CT / API 5B

Grade:

K55

Thickness:

3.5-60mm

Shape:

Round

Outer Diameter:

Ф 60.3-114.3 mm

Place of Origin:

Inner Mongolia, China

Usage:

Transportation of oil and gas

Surface Treatment:

Hot Rolled

Tolerance:

WT: -12.5% OD:< 4 1/2 ±0.79 mm ;≥ 4 1/2 +1%D ~ -0.5%D

End:

Plain

End Protector:

HDPE crash cap or customized

length:

R1, R2, R3

Brand:

Baotou steel

Delivery Time:

Normally within 30-45 days and according to the quantity.

Chemistry Component(API 5CT)

| Grade | C | Mn | Mo | Cr | Ni | Cu | P | S | Si | ||||

| Min | Max | Min | Max | Min | Max | Min | Max | Max | Max | Max | Max | Max | |

| K55 | – | – | – | – | – | – | – | – | – | – | – | 0.030 | 0.030 |

Mechanical Property(API 5CT)

| Grade | Total under load Elongation % | Yield strength megapascal | Tensile strength megapascal | Hardness a, C Maximum | Specified OD mm | Allowable hardness Variation | ||

| Min | Max | Min | HRC | HBW | HRC | |||

| K55 | – | 0.5 | 379 | 552 | 655 | – | – | – |

Case:

Our K55 tubing is specially designed for shallow and medium production tubing columns to achieve efficient fluid transfer and gas lift optimization at well depths ≤3500m and H₂S ≤50ppm. The core application is used in the production tubing Φ73mm in Changqing Surig tight gas field and gas lift system in Sahara oil field in Egypt. We also provide K55 with solution for Orinoco heavy oil development in Venezuela to ensure the integrity of tubing column in high temperature and high pressure environments.

Related products

API 5CT L80-1 Tubing for Shale Gas

Read More

GB/T 18248 42CrMo Gas Cylinder Tube

Read More

GB/T 18248 34CrMo4 Gas Cylinder Tube

Read More

GB/T 3077-2015 20Cr Seamless Alloy Steel Pipe

Read More

Heavy Rail of P65/R65 Rails

Read More

Liquid Epoxy Coating

Read More

API 5L Seamless Pipeline Tube X42-X70 PSL2

Read More

API 5CT K55 Tubing With LC Thread Connection

Read More