Common Packaging Methods for OCTG Casing and Tubing

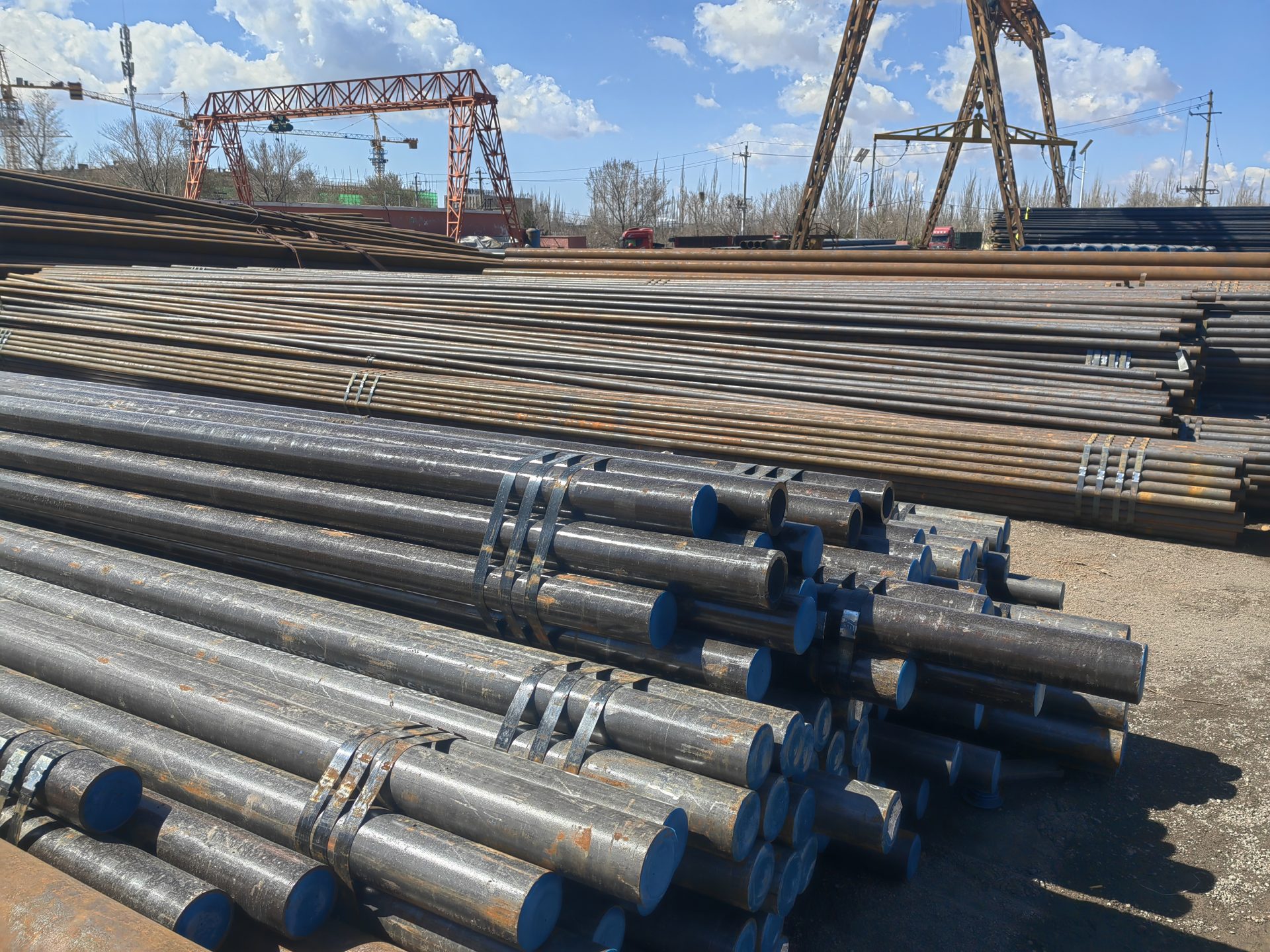

1.Bundling with Steel Straps

One of the most common and cost-effective methods is bundling the pipes using high-strength steel straps. This method is widely used for medium- to large-diameter casing and tubing.

Procedure:

Pipes are arranged in hexagonal or square bundles.

Heavy-duty steel straps (typically galvanized) are used to secure the bundle at multiple points.

Spacers or rubber inserts may be added to prevent movement and reduce friction.

2.Plastic or Wooden End Caps

OCTG casing and tubing often feature threaded connections, which must be protected from damage. Plastic or wooden end caps are used to cover the ends of the pipes.

Procedure:

End caps are applied to both ends of the pipes after machining.

Caps are secured to prevent removal during transportation.

3.Protective Wrapping (Plastic or VCI Paper)

Pipes can be wrapped in plastic sheeting or Vapor Corrosion Inhibitor (VCI) paper to enhance protection against corrosion.

Procedure:

Each pipe is wrapped individually or in bundles.

Heat-sealed plastic wrapping or shrink film may be used for added security.

4.Wooden or Steel Crates

For premium OCTG pipes or small-diameter tubing, wooden or steel crates provide additional protection.

Procedure:

Pipes are placed inside customized crates with foam or padding.

Crates are sealed to prevent environmental exposure.

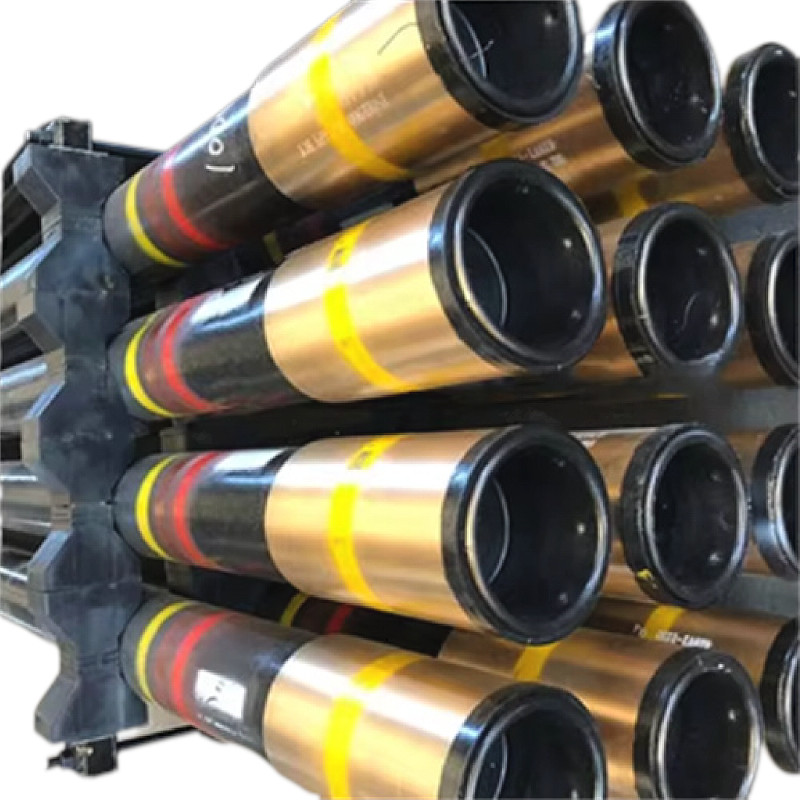

5.Thread Protectors and Coupling Protectors

Since the integrity of threaded connections is crucial, heavy-duty plastic or steel thread protectors are commonly used.

Procedure:

Protectors are screwed onto the pipe ends.

Some versions include moisture-resistant seals for extra protection.