Introduction

In the world of railway engineering, selecting the correct rail profile is the most critical decision for safety, durability, and cost-efficiency. From high-speed passenger lines to heavy-duty industrial mining tracks, different types of steel rails are engineered to meet specific mechanical demands. This guide breaks down the major categories of steel rails used globally and their primary applications.

1. Heavy Rails: The Backbone of Global Transportation

Heavy rails generally refer to rail profiles with a weight greater than 30 kg per meter. These are used for major transportation networks where high strength and wear resistance are paramount.

P65 / R65 (GOST Standard)

Primary Region: Uzbekistan, Kazakhstan, Russia, and other CIS countries.

Application: Heavy-haul freight corridors and main passenger lines.

Why it’s chosen: Specifically designed for extreme temperature fluctuations and high-stress environments. It is the standard for the 1520mm gauge network.

UIC 60 / 60E1 (European Standard)

Primary Region: Europe, Southeast Asia, and Middle East.

Application: High-speed rail (HSR) and standard international passenger lines.

Why it’s chosen: Manufactured to extremely tight tolerances for smoothness, allowing trains to exceed speeds of 250 km/h.

136 RE / 115 RE (AREMA Standard)

Primary Region: North America, South America, and Australia.

Application: Heavy-haul mining railways (e.g., iron ore and coal transport).

Why it’s chosen: Built with a thicker web and head to withstand the highest axle loads in the world.

2. Light Rails: Industrial and Mining Powerhouses

Light rails weigh 30 kg per meter or less. They are versatile, easy to install, and ideal for short-distance logistics.

Common Sizes: 12kg, 15kg, 22kg, 30kg.

Primary Applications:

- Underground Mining:Narrow-gauge tracks for ore carts.

- Forestry & Agriculture:Temporary tracks for transporting timber or crops.

- Theme Parks:Infrastructure for sightseeing trains and light recreational rails.

Key Advantage: Highly portable and cost-effective for private industrial sites.

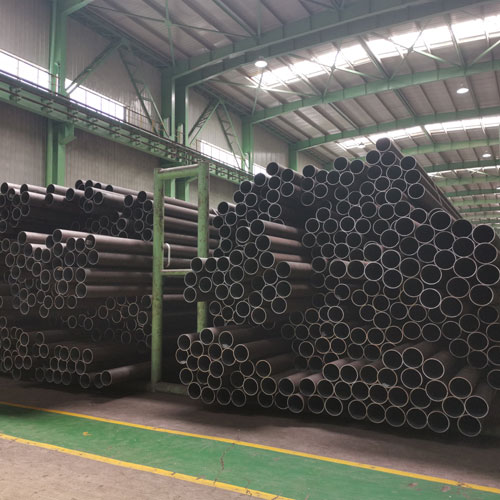

3. Crane Rails: Specialized Vertical Logistics

Crane rails (such as QU70, QU100, or A100) differ significantly from railway rails. They feature a wider head and a thicker base with a lower center of gravity.

Applications: Port terminals (Gantry Cranes), massive steel mill warehouses, and automated overhead cranes.

Key Advantage: Designed to absorb massive vertical pressure and lateral torque from heavy lifting machinery.

4. Grooved Rails: Urban Tram Solutions

Grooved rails (e.g., Ri59, Ri60) are specialized for “embedded” tracks in urban environments.

Applications: City tramways and light rail transit (LRT) running through street pavement.

Why it’s chosen: The built-in groove protects the wheel flange, allowing the track to be level with the road surface so cars and pedestrians can cross safely.

Summary Table: Rail Selection at a Glance

| Rail Category | Typical Profile | Primary Application | Key Requirement |

| Heavy Rail | P65, UIC 60 | National Railways | High Load & Speed |

| Light Rail | 24kg, 30kg | Mining & Temporary | Portability & Cost |

| Crane Rail | QU80, A120 | Ports & Factories | Vertical Pressure |

| Grooved Rail | Ri60 | City Trams | Street Integration |

How to Source the Right Rail?

When requesting a quote for your project, ensure you provide the following technical data:

Standard: (GOST, EN, AREMA, or GB?)

Steel Grade: (e.g., 900A, R260, or U71Mn?)

Axle Load: What is the maximum weight per axle of the vehicle?

Length: Standard 12m, 12.5m, 25m, or custom lengths?

Conclusion

Selecting the right steel rail ensures the longevity of your infrastructure and reduces maintenance costs. Whether you are building a new freight line in Central Asia or a port facility in Africa, understanding these profiles is the first step to success.