In the world of Oil Country Tubular Goods (OCTG), the threaded connection is often the most critical point of a well’s design. These joints must maintain structural integrity and pressure seals under extreme axial loads, internal pressures, and corrosive environments.1 Choosing between API standard threads and Premium threads is a decision that impacts both the safety and the economic viability of drilling and production operations.

1. API Standard Thread Connections

The American Petroleum Institute (API) provides the industry benchmark for standardized connections. These are designed for interchangeability, meaning a pipe from one manufacturer can be mated with a coupling from another, provided both meet API specifications.

Common API Thread Types

- API Round Thread (8RD):Used primarily for tubing.

EUE (External Upset End): The pipe end is thickened (upset) to provide higher joint strength than the pipe body.

NUE (Non-Upset End): Used where mechanical strength requirements are lower.

- API Buttress Thread (BTC):A square-shouldered thread used for casing. It offers superior tensile and compressive strength compared to round threads, making it suitable for deeper wells.

- API Line Pipe (LP):Used for surface-level gathering systems and low-pressure transmission.

Pros and Cons of API Threads

| Advantages | Limitations |

| Cost-effective and widely available. | Not gas-tight; relies on “thread dope” (compound) to seal. |

| Global interchangeability. | Lower resistance to high torque and bending. |

| Simple manufacturing and inspection. | Limited performance in HPHT (High-Pressure High-Temp) wells. |

2. Premium Thread Connections

As wells become deeper, hotter, and more complex (e.g., horizontal or deepwater), API threads often reach their physical limits. Premium connections are proprietary designs engineered to exceed API standards.

Why Upgrade to Premium?

The defining feature of a premium connection is the metal-to-metal seal. While API threads rely on the interference of threads and grease to stop leaks, premium threads feature a machined metal surface that creates a gas-tight barrier.

- Enhanced Torque:Designed to withstand the high rotational forces required in directional drilling.

- Flush or Slim-line Profiles:Useful for restricted borehole clearances.

- Fatigue Resistance:Specifically engineered to survive the “bending” stresses found in horizontal wellbore transitions.

3. Engineering Design Criteria

When selecting a connection, engineers evaluate five primary mechanical factors:

- Mechanical Strength:The connection must support the weight of the entire pipe string (Tensile) and resist “crushing” forces (Compression).

- Sealing Integrity:Is the well producing dry gas? If so, a metal-to-metal premium seal is mandatory to prevent leaks.

- Bending Capacity:In horizontal wells, connections must endure “Dogleg Severity” (DLS) without cracking or losing their seal.

- Make-up Torque:The design must allow for consistent assembly at the rig site without over-stressing the steel.

- Corrosion Resistance:Special coatings (like phosphating) or specialized alloys are used to prevent “galling” during assembly and corrosion during production.

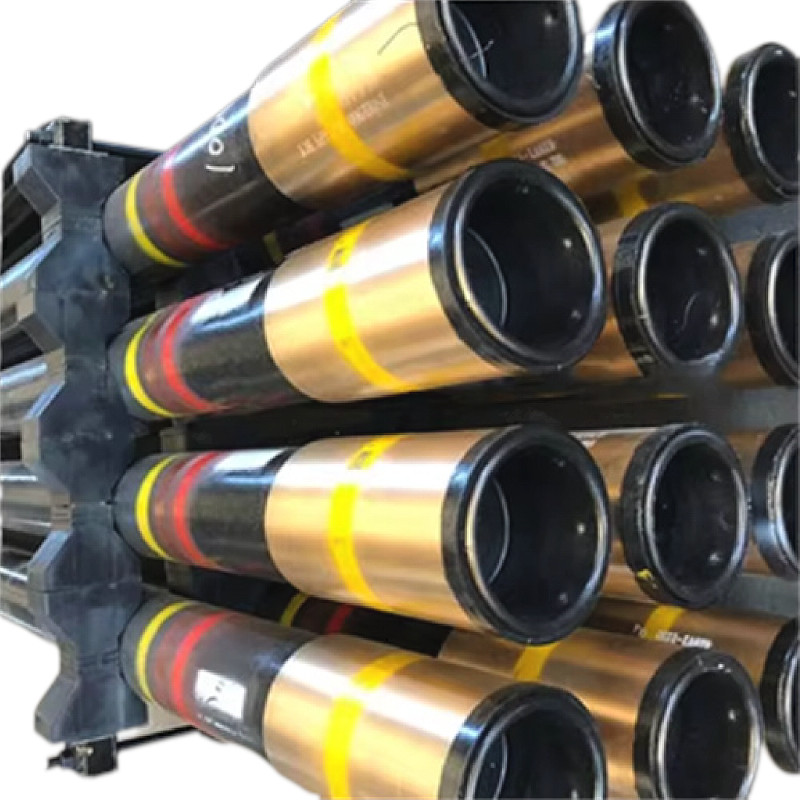

4. The Threading & Manufacturing Process

Precision is the hallmark of OCTG manufacturing. A single microscopic flaw can lead to a multi-million dollar well failure.

- Machining:CNC (Computer Numerical Control) lathes cut the specific thread profile, taper, and lead onto the pipe end.

- Gauging:Using API-standard or proprietary gauges to ensure the thread dimensions are within microns of the design.

- Surface Treatment:Applying phosphate or specialized coatings to reduce friction and prevent corrosion.

- Testing:Hydrostatic testing involves filling the pipe with water at high pressure to ensure no leaks exist in the connection.

5. Leading Proprietary Premium Brands

Several global manufacturers dominate the premium connection market, each offering specialized geometries for specific challenges.

VAM® (Vallourec)

The industry benchmark for gas-tight performance. VAM TOP® is widely used in offshore environments, while VAM 21® offers advanced fatigue resistance for the most demanding HPHT wells.

TenarisHydril®

Known for the Wedge™ series. These threads use a unique interlocking geometry that provides exceptional torque and compression resistance, making them ideal for “shale” applications and extended-reach wells.

Hunting Premium Connections

The SEAL-LOCK® family is a staple for high-performance tubing and casing, offering reliable metal-to-metal sealing in deepwater and horizontal applications.

JFE & NOV XT

- JFE (Japan):Their FOX® and BEAR® connections are optimized for high-torque and corrosive environments.

NOV XT (USA): Specifically engineered for drill pipe applications, providing massive torsional capacity for deep-hole drilling.

Conclusion: Selecting the Right Joint

The choice between API and Premium connections is a balance of risk vs. cost. While API threads are sufficient for shallow, vertical, low-pressure wells, the extreme conditions of modern offshore and unconventional drilling almost always necessitate the superior sealing and mechanical strength of Premium connections.