In the engineering world, selecting the right material is not just a choice—it’s the cornerstone of safety, efficiency, and longevity. Alloy steel pipes, engineered by infusing carbon steel with elements like chromium, molybdenum, nickel, and vanadium, deliver far superior strength, corrosion resistance, and performance under extreme conditions. But where does this enhanced capability matter most? The answer lies at the heart of industries that push materials to their limits.

While alloy steel pipes serve countless functions, their most critical and widespread applications define the modern industrial landscape. Here is where they prove indispensable:

- Conquering the Extremes: Oil & Gas Exploration & Production

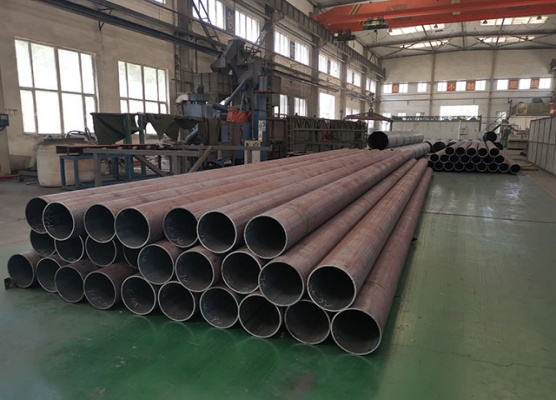

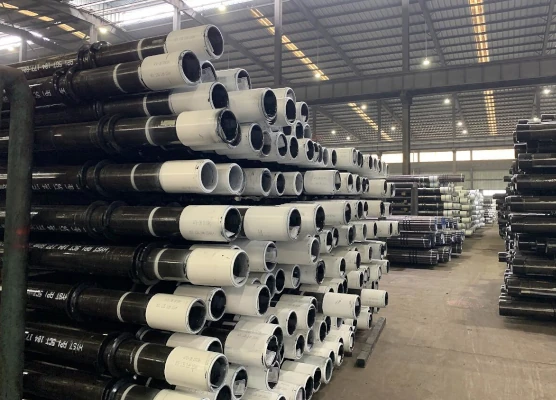

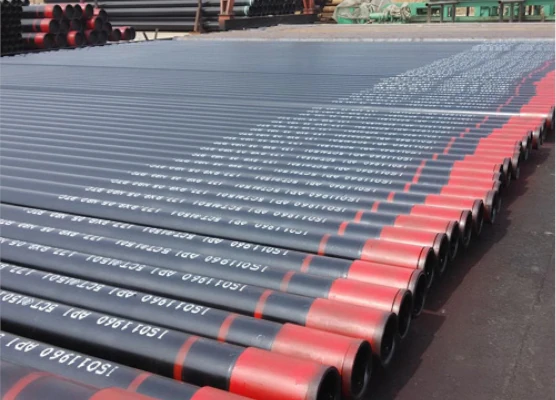

In the quest for energy, operations delve into some of Earth’s most hostile environments. Alloy steel pipes are the frontline warriors here.

- Downhole Tubing & Casing: In deep, high-pressure, and “sour” wells (containing H₂S), specialized grades like L80 or C95 resist sulfide stress cracking and collapse, ensuring well integrity.

- Refinery & Petrochemical Piping: From catalytic cracking units to hydroprocessing lines, pipes must withstand corrosive chemicals, hydrogen attack, and temperatures exceeding 1,000°F. Chrome-molybdenum alloys (e.g., P5, P9, P11) are the standard for this punishing service.

- Harnessing Heat & Pressure: Power Generation

Whether fueled by coal, gas, or nuclear fission, power plants rely on converting heat into energy. Alloy steel pipes form the critical circulatory system.

- Boiler Tubes & Superheaters: These components carry steam at extreme pressures and temperatures (often 1000+ psi and 1000+ °F). Alloys like P22 and the advanced P91 provide exceptional creep strength—resisting deformation over decades of operation.

- High-Pressure Steam Lines: Transporting this superheated steam to turbines demands pipes that won’t fail under thermal fatigue and constant stress.

- Containing the Corrosive: Chemical & Petrochemical Processing

This industry deals with some of the most aggressive media imaginable—acids, alkalis, and solvents. Alloy steel pipes, particularly stainless grades, act as impervious barriers.

- Reactor Feed/Effluent Lines: They safely convey reactive raw materials and products to and from reaction vessels.

- Heat Exchanger Tubing: In condensers and coolers handling corrosive fluids, alloy tubes offer optimal thermal conductivity while resisting pitting and erosion.

- Building with Strength: High-Performance Mechanical & Structural Uses

Beyond fluid transport, the superior strength-to-weight ratio of alloy steel pipes makes them ideal structural components.

- Hydraulic Systems: Used for high-pressure hydraulic cylinders and tubing in heavy machinery, where burst resistance is critical.

- Automotive & Aerospace: In roll cages, chassis components, and landing gear assemblies, alloy pipes provide maximum strength with minimum weight.

- Bearing & Machinery Parts: Their wear resistance and durability are key for rotating parts and high-stress connections.

- Enabling Efficiency: Heat Exchangers & Condensers

Across industries, efficient heat transfer is vital. Alloy steel tubes in these applications offer:

- Resistance to Scaling & Fouling: Maintaining clean inner walls for optimal heat exchange.

- Compatibility with Diverse Media: Whether on the shell side or tube side, they withstand both the process fluid and the coolant.

Why Choose the Right Alloy Steel Pipe Matters

Selecting the correct grade is not a generic decision. It requires precise matching of the pipe’s properties to the specific application’s demands. To illustrate the critical impact of this choice, consider this comparison:

Project Scenario: A new natural gas processing plant requires piping for a high-pressure gas stream containing 5% CO₂ and trace H₂S at 400°F (204°C) and 1500 psi.

| Piping Choice | Key Data / Specification | Projected Outcome (Based on Industry Data) |

| Standard Carbon Steel (A106 Gr. B) | Cost:$Base Reference<br>Corrosion Rate in wet CO₂ service: High (potentially >0.1 mm/yr) | Higher Risk & Cost Over Time:Unplanned shutdowns due to wall thinning or leaks likely within 5-7 years. High maintenance and replacement costs. Potential safety incidents. |

| Optimized Alloy Steel (A335 P11) | Cost:~1.5x – 2x Base Cost<br>Corrosion Rate: Very Low (<0.01 mm/yr)<br>Yield Strength:~415 MPa (vs. 240 MPa for A106B) | Reliable & Cost-Effective: Design life extended to 20+ years without major repairs. Minimal unplanned downtime. Total Cost of Ownership (TCO) is significantly lower despite higher initial investment. |

Conclusion: The Strategic Investment in Superior Performance

The data clearly shows that the true cost of a pipe is measured over its entire service life, not just its initial purchase price. Alloy steel pipes, while commanding a premium upfront, are a strategic investment in operational integrity. They deliver:

- Enhanced Safety:Minimizing the risk of catastrophic failure in critical systems.

- Maximized Uptime: Reducing unplanned shutdowns for maintenance and repairs.

- Optimized Total Cost of Ownership (TCO): The long-term savings in maintenance, replacement, and avoided production losses far outweigh the initial material cost difference.

IMRI: Your Expert Partner for Application-Driven Solutions

We understand that behind every specification is a real-world challenge. Our role is to provide more than just alloy steel pipe; we deliver certified, application-optimized solutions that ensure your project’s integrity from the ground up. With deep technical expertise across these core industries, we help you select the ideal material to enhance safety, maximize uptime, and achieve total cost efficiency.

Ready to specify the right pipe for your critical application? Contact our engineering team today for a consultation. Let us help you build with confidence.