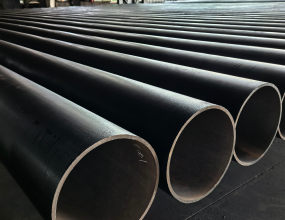

In oil extraction, special environments pose extremely stringent tests on the performance of tubing. Different tubing grades need to be matched to deal with such conditions.

In the deep – well environment with high temperature and high pressure, tubing of P110 grade can play a significant role. The yield strength of this type of tubing can reach 930 MPa, and the tensile strength is approximately 1100 MPa. Even under temperatures of several hundred degrees Celsius and pressures of dozens of megapascals, it can still maintain stability and reliably transport oil. For example, in the exploitation of some ultra – deep wells in western China, P110 – grade tubing undertakes the crucial task of oil transportation.

In highly corrosive environments, such as oil wells containing corrosive gases like hydrogen sulfide and carbon dioxide, C90 – grade tubing stands out with its excellent corrosion – resistance. While maintaining a certain strength (yield strength of around 620 MPa), it shows good tolerance to various corrosive media. This effectively extends the service life of the tubing and reduces maintenance costs, and is widely used in many sulfur – containing oil wells in the Middle East.

In low – temperature environments, such as polar regions or deep – sea low – temperature areas, N80Q – grade tubing performs outstandingly. Based on ensuring a yield strength of approximately 552 MPa, special alloying elements are added, which significantly enhances low – temperature toughness. It can effectively resist the risk of low – temperature cracking and ensure the smooth progress of oil extraction. It plays an important role in some offshore oil wells in the Arctic region.