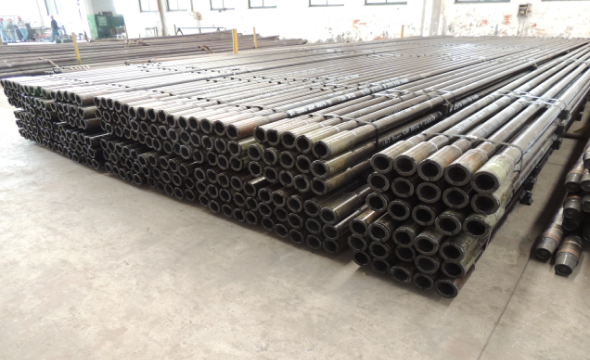

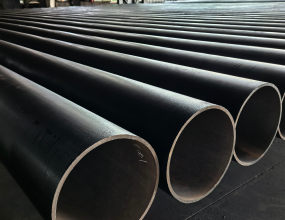

Tubing is a key component in oil extraction operations. The tubing is made from high quality steel billets, which are processed into tubes with specific diameters and wall thicknesses through an advanced hot rolling process. Subsequently, the tubes are subjected to rigorous non-destructive testing to ensure that there are no internal defects. In order to enhance the corrosion resistance, the tubing will be treated with a special anti-corrosion coating, which is tightly adhered to the surface of the tubing body, effectively resisting the erosion of complex media in the oil well. These processes guarantee the long-term stable operation of the tubing in the harsh oil well environment.

- Tubes et tuyaux de tubage, tuyauterie

OCTG API 5CT 5B Tubing for oil gas field

Email:

sales@imristeel.com

Phone:

+86 13646172523

Quote Now

Product Details

Packaging & Delivery

Produits connexes

Product Detail

Tubing is a key component in oil extraction operations. The tubing is made from high quality steel billets, which are processed into tubes with specific diameters and wall thicknesses through an advanced hot rolling process. Subsequently, the tubes are subjected to rigorous non-destructive testing to ensure that there are no internal defects. In order to enhance the corrosion resistance, the tubing will be treated with a special anti-corrosion coating, which is tightly adhered to the surface of the tubing body, effectively resisting the erosion of complex media in the oil well. These processes guarantee the long-term stable operation of the tubing in the harsh oil well environment.

Quick Details

Standard:

API 5CT API 5B

Grade:

J55 N80 L80 C90 P110

Thickness:

4.24-9.96mm

section shape:

Round

Outer Diameter:

Ф60.3-114.3

Place of origin:

Baotou, China(Mainland)

Application:

Petrochemicals

Technique:

Hot Rolled, Seamless

Certification:

API

Surface Treatmen:

According to customers request

Alloy Or Not:

Both

length:

1-12m

Supply Ability:

( 40.0000 )Ton/Tons per year

End:

EUE;NU

Specification:

steel pipe

Brand:

Baotou steel

Technique:

seamless

Finish:

Hot Rolled

Chemistry Component

| Grade | C | Mn | p | S | V | Nb | Ni | |

| Max. | Max.b | Min. | Max. | Max. | Max. | Max. | Max. | |

| L210 a | 0.22 | 0.9 | 0.03 | 0.03 | 0.03 | – | – | – |

| L245 b | 0.28 | 1.2 | 0.03 | 0.03 | 0.03 | c,d | c,d | c,d |

| L290 x42 | 0.28 | 1.3 | – | 0.03 | 0.03 | d | d | d |

| l320 x46 | 0.28 | 1.4 | – | 0.03 | 0.03 | d | d | d |

| L365 x52 | 0.28 | 1.4 | – | 0.03 | 0.03 | d | d | d |

| L390 x56 | 0.28 | 1.4 | – | 0.03 | 0.03 | d | d | d |

| L415 x60 | 0.28e | 1.40e | – | 0.03 | 0.03 | f | f | f |

| L450 x65 | 0.28e | 1.40e | – | 0.03 | 0.03 | f | f | f |

| L485 x70 | 0.28e | 1.40e | – | 0.03 | 0.03 | f | f | f |

Tensile test requirements

| Steel grade | Yield strength | Tensile strength | Elongation |

| Mpa(psi) | Mpa(psi) | (50mm or 2inn) | |

| L210 or A | 210(30500) | 335(48600) | c |

| L245 or B | 245(35500) | 415(60200) | c |

| L290 or X42 | 290(42100) | 415(60200) | c |

| L320 or X46 | 320(46400) | 435(63100) | c |

| L365 or X52 | 360(52200) | 460(66700) | c |

| L390 or X56 | 390(56600) | 490(71100) | c |

| L415 or X60 | 415(60200) | 520(75400) | c |

| L450 or X65 | 450(65300) | 535(77600) | c |

| L485 or X70 | 485(70300) | 570(82700) | c |

Packaging & Delivery

Packaging & Delivery

· Packaging Details: Bundles wrapped with strong steel trips, caps on two ends of every pipe or according to customers’ requirements.

· Port: Tianjin Port

· Lead Time: Within 20-30 days depends on the order quantit

· Port: Tianjin Port

· Lead Time: Within 20-30 days depends on the order quantit

Packaging & Shipping

· Minimum order quantity: 5 tons

· Price: FOB or CIF or CFR at Xin’gang port in Tianjin

· Payment: 30% deposit in advance, the balance against the copy of B/L; or 100% L/C, etc

· Lead Time: within 10-25 workdays normally

· Packing: Standard seaworthy packing or as per your request .(as pictures)

· Sample: Free sample is available.

· Price: FOB or CIF or CFR at Xin’gang port in Tianjin

· Payment: 30% deposit in advance, the balance against the copy of B/L; or 100% L/C, etc

· Lead Time: within 10-25 workdays normally

· Packing: Standard seaworthy packing or as per your request .(as pictures)

· Sample: Free sample is available.

Produits connexes

35CrMo alloy tube

Lire la suite

Ethylene Vinyl Alcohol Copolymer (EVOH)

Lire la suite

Seamless Pipe

Lire la suite

3PE Anti-corrosion Steel Pipe Epoxy Coating Reinforce Grade Gas Pipeline1

Lire la suite

Seamless Pipe

Lire la suite

Seamless Pipe

Lire la suite

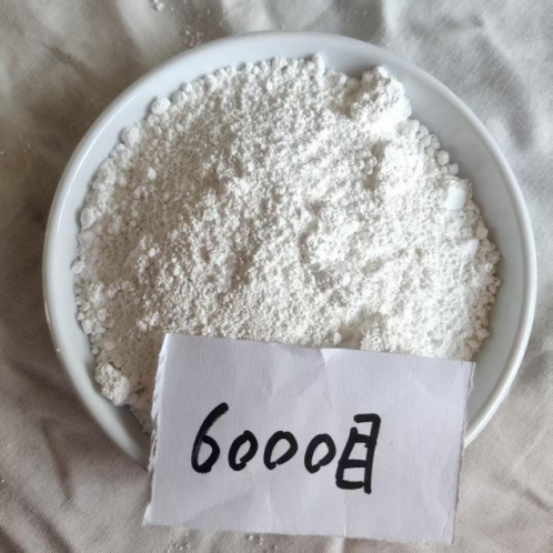

Kaolin Supplier

Lire la suite

Seamless Pipe

Lire la suite