product list

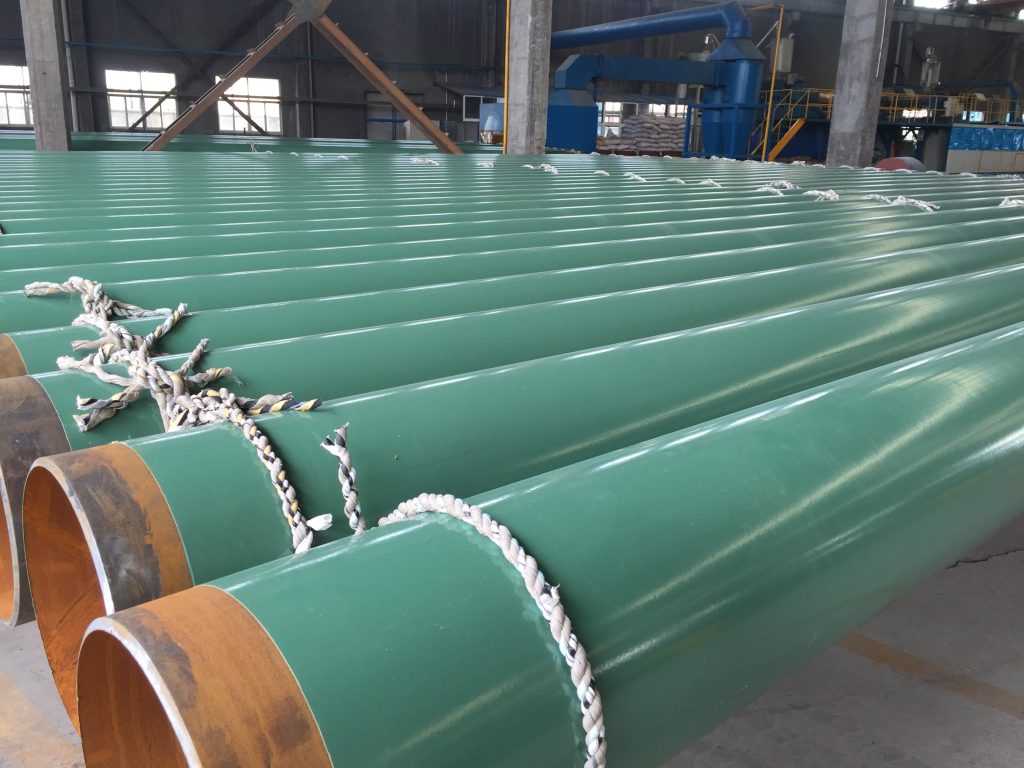

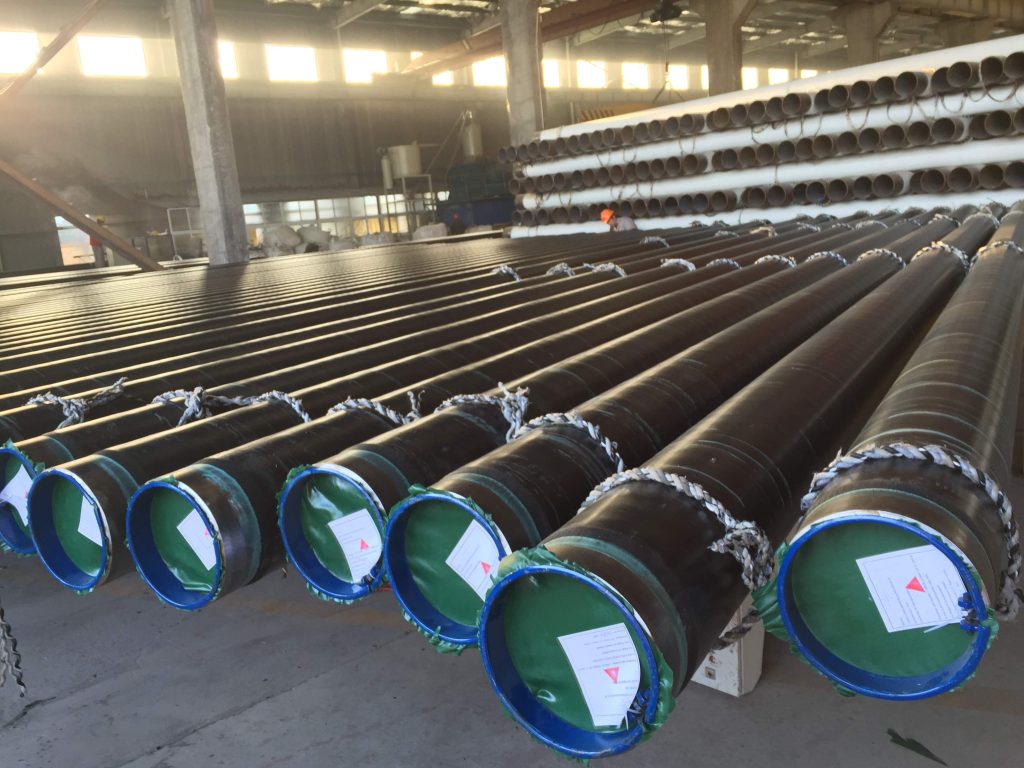

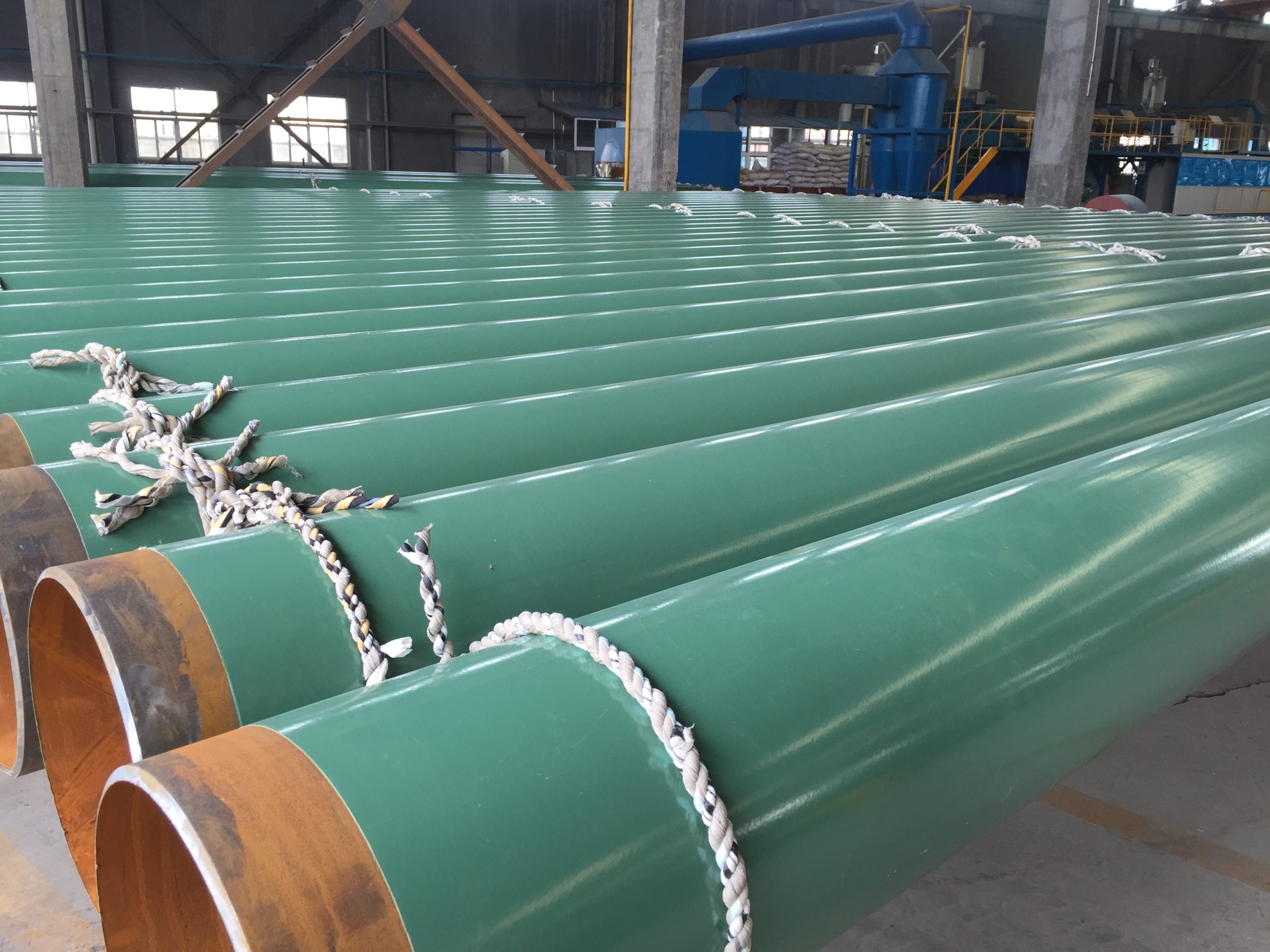

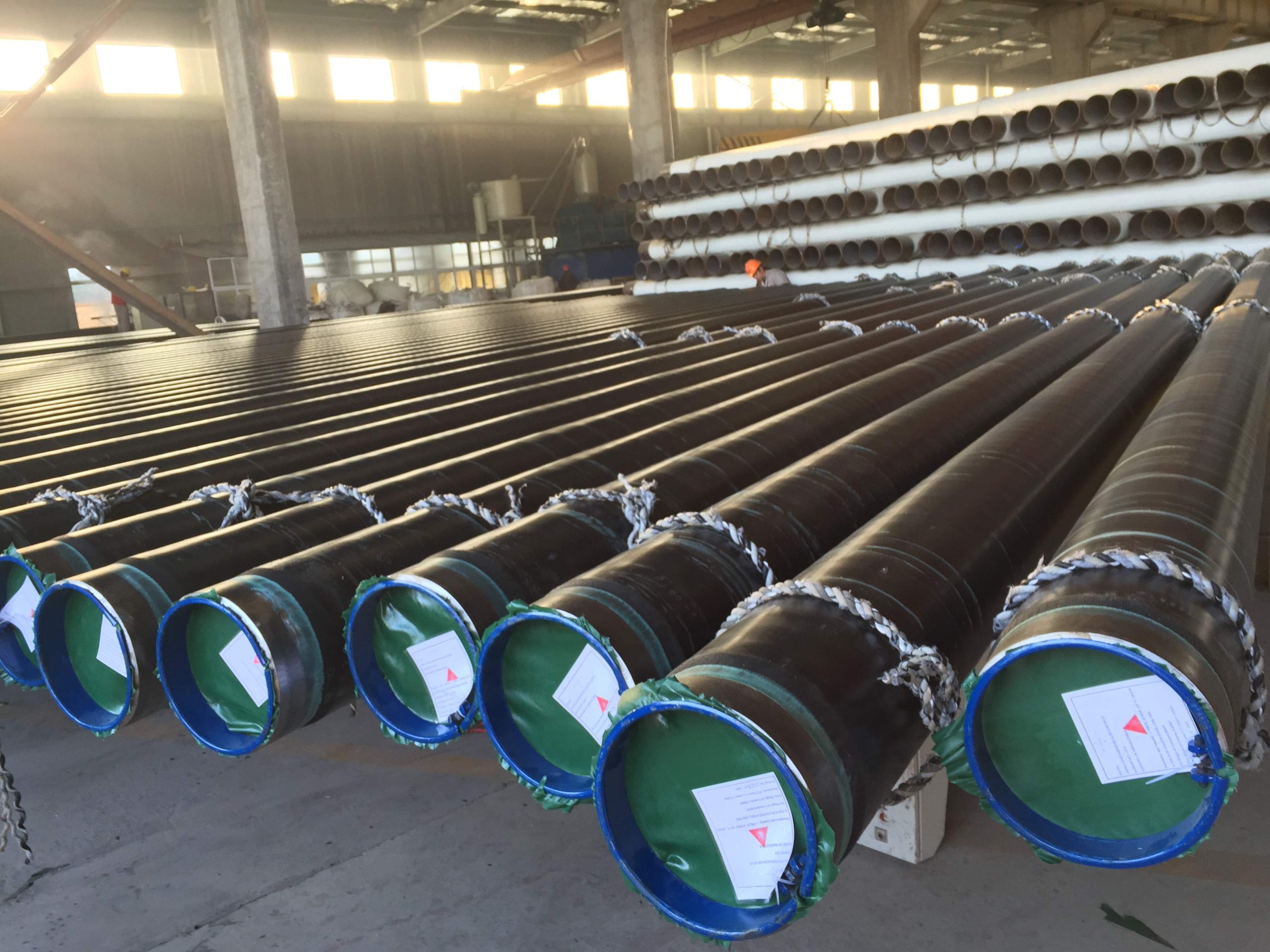

FBE coating Pipe

Use:Widely used in long-distance anti-corrosion pipelines on land and underwater.

FBE coating material is thermosetting material, it is consist of solid epoxy resin, curing agent and various additives by mixing, grinding. Heating,then FBE powder is sprayed on the surface of the pipe by electrostatic adsorption method, FBE powder is heated and cooled melt adhesive curing. Single-layer FBE coating thickness is about 300-500um, DPS (Double layer FBE) thickness is controlled in 450-1000um.

FBE coating has the properties of excellent adhesive strength, high insulation resistance, resistance to soil stress, anti-aging, anti-cathode stripping, anti-high temperature, resistance to bacteria and small cathodic protection current(only 1-5uA/㎡), etc. But there are also poor performances against mechanical impact, high water absorption and other shortages.

coating standards as per SY/T0315、CAN/CSA Z245.20、AWWA C213、Q/CNPC 38,etc.

FBE Coated Pipes Specification

| Product: | FBE (Fusion Bond Epoxy) Coated Pipes, Epoxy Coated Carbon Steel Pipes |

| Application: | Used for Coal mine,heat and power plant,oil and gas transmission |

| Standard: | DIN30670,CAN/CSA-Z245.21 |

| Size: | OD:219-2000MM |

| Pakcing: | in bundles, in loose, Nylon Strip for each bundle for piece pipes |

| Color | RAL colors coating powder |

| Service: | anti-chemical corrosion and water resistance strong |